An idea emerges and you hop to the drawing board, itching to see what comes to life. In most scenarios, this first iteration is probably not what you had in mind. Rather, the design will be modified for any number of reasons. This can be especially true when designing jewelry. A ring, bracelet, necklace or any accessory must fit, hold an appropriate scale, meet your personal aesthetic, and retain important details. All of these facets of the design can be perfected when brought to life with prototyping.

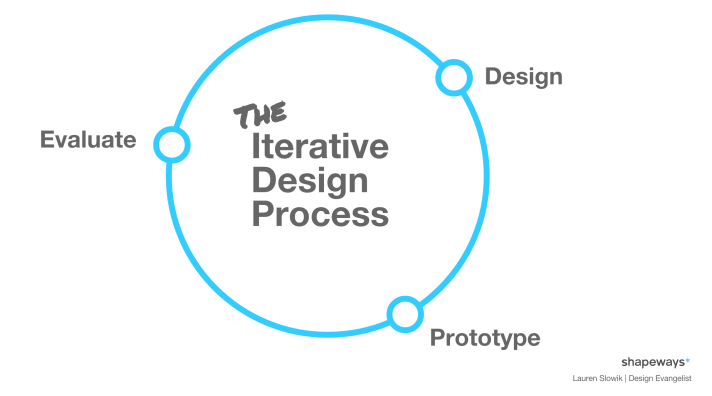

The cycle of designing has no beginning or end because your process may start at any given point and continue any number of times. Prototyping is one step within this iterative process, and it allows you to take a step back and consider how you can improve your design.

print a prototype

When should you prototype?

Consider it necessary to prototype when you are looking to create jewelry with custom sizes or settings, such as stone settings. By prototyping these products you can ensure that the piece of jewelry or stone will fit correctly for your final iteration.

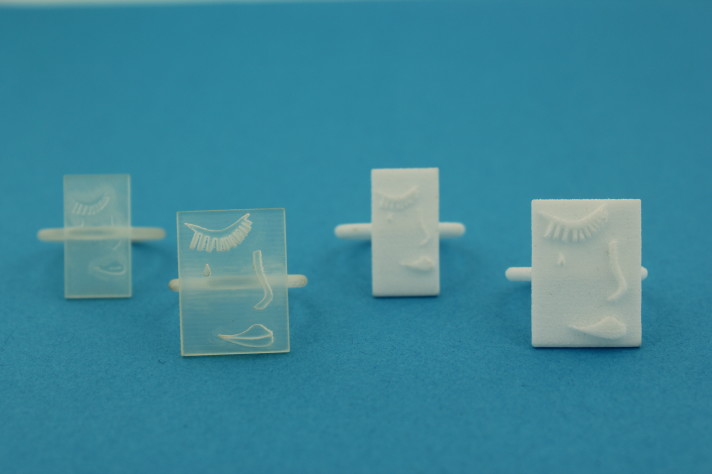

In the early stages, it is best to prototype your jewelry design before selling to the public. Printing in a more low cost material to start gives you the opportunity to evaluate the scale and fit of your product, and will save you from returns and excess spending. Once you’ve approved your prototype, you can move onto some of our precious metal materials.

The difference between a render and a physical object is greater than one may anticipate. Although measuring your model will provide you with concrete dimensions, there is nothing like holding a design in your hand. In my experience the scale of certain design features or even the entire product are always larger or smaller than I prefer. With this intermediary step, I get the opportunity to correct and improve upon this.

What material should you prototype in?

While your final design will most likely be printed in a cast metal or steel, your initial prototypes will not require one of these materials with a longer lead time and higher price point. Instead, initial prototyping can be printed with frosted ultra detail or strong and flexible. These materials are great for quick turn around and a fair understanding of the overall look and fit of your final product.

This material is great for a clean and high detail finish, particularly if you are looking to print your final model in a cast metal.

For a lower price point prototype, you can print in strong and flexible. This material is also offered in rush production, for those who need to move quickly.

TIP: Please do keep in mind that different materials have similar but different guidelines. Make sure that while you are prototyping you are following the guidelines of the material you will ultimately be printing in.

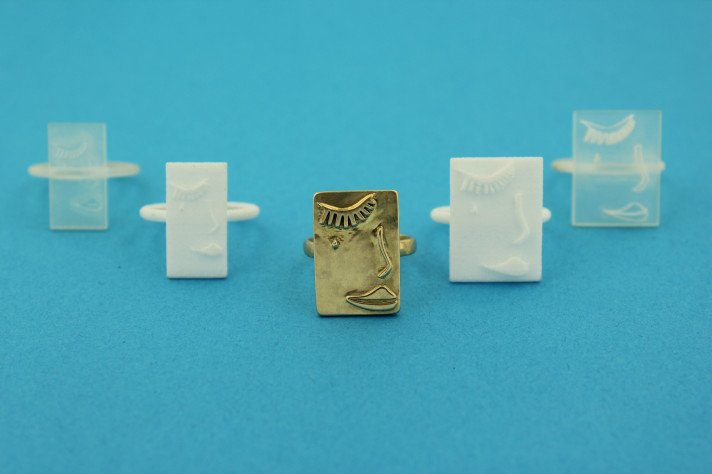

Now after the initial prototypes are completed and you have made another cycle through the Iterative Design Process, a final prototype can be created in a beautifully polished or unpolished cast metal such as brass or bronze. These are particularly beneficial when looking to print your final model in silver, platinum, gold, or a precious plated metals.

Brass and bronze are significantly less expensive and go through a similar production process as the other cast metals. These cast metal prototypes will demonstrate the extent of polishing you can expect and which tiny details will be able to make it through the production process.

A prototype can be the stepping stone to a finalized design or even an inspiration for your next project. Skipping this step can be a missed opportunity to creating that perfect piece of jewelry.

Want to know how Shapeways can be your partner from prototyping to manufacturing? Contact us today and find out the ways we can help you grow.

I don’t really know much about jewelry prototyping until I came across your article. I like the fact that a prototype is strong and flexible. They match with just about any type of jewelry in the market. the design looks simple yet elegant. I will be reading more about prototyping to get a better understanding of the process of jewelry designing. Thanks.