The 3D printing realm has grown almost unfathomably vast in a relatively short period of time, encompassing infinite potential for innovation in nearly every part of the world. Options in materials and technology continue to grow. This is definitely the case at Shapeways, where customers enjoy access to many different types of additive manufacturing, as well as unique and traditional methods of production.

Create a First-Rate 3D File

Quality designs lead to quality parts, but it’s not always an easy process. Some very important steps must occur before it is possible for a 3D model to make it into a 3D printer. A healthy dose of inspiration and motivation is required first—leading to the ideation phase—which must be accompanied by tools meant to streamline the process from modeling to manufacturing.

Shapeways works with customers every day who are dedicated to designing unique 3D models for a tremendous range of projects, varying in requirements that affect options in terms of settings, materials, and technology. This is why the ongoing design partnership with ZVerse has been so positive for simplifying the customer experience. ZVerse was a logical partner due to the massive scope of 3D printing going on at Shapeways—leading to the need for a professional design team with broad resources.

The ZVerse platform is uniquely AI-enabled, allowing for better automation in file creation workflow, along with helping Shapeways scale to customer needs better. Every customer has access to comprehensive design solutions offering the most streamlined path from concept to 3D model.

3D printing experts from the Shapeways User Application Team are also available for one-on-one consultations to discuss the best fit for materials and manufacturing methods, as well as finding ways to overcome typical issues with printability.

“We are here to help with any and all questions about design, materials, or the processes that make our customers’ models come to life,” says Zach Dillon, User Application Team Lead at Shapeways.

Get the most out of product development

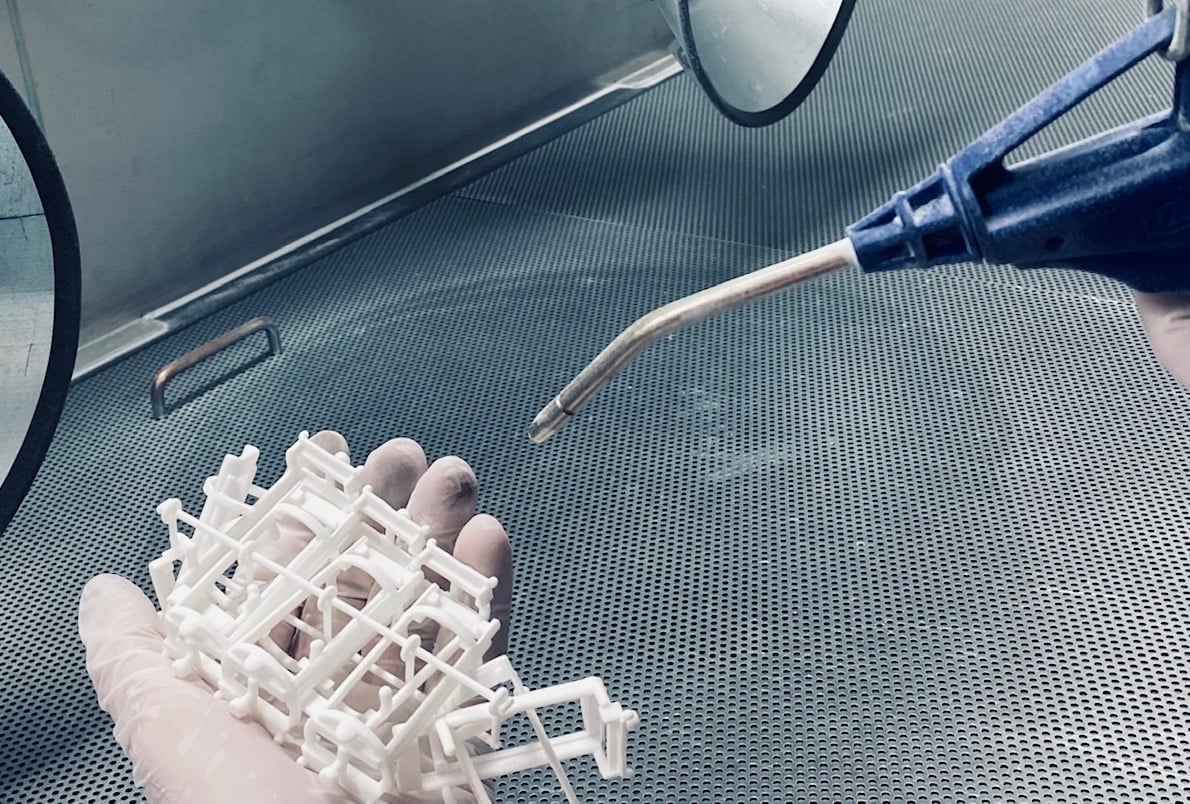

While 3D printing allows for incredible creativity, innovation, and the ability to make products with complex geometries that simply were not possible previously, this technology lends itself to superior product development processes, beginning with rapid prototyping. Models can be designed and 3D printed, offering detailed visualization of products, along with the ability to test and validate parts according to project specifications. A good example would be checking for proper fit in new automotive parts or aerospace applications where there is absolutely no room for error. Rapid prototyping has played a major role for customers like Tilt Hydrometer, with CEO Noah Neibaron designing and 3D printing over a hundred iterations with Shapeways before settling on the final design for his free-floating monitoring device used in homebrewing.

Shapeways 3D prints products in over 90 materials and finishes, with over 11 technologies to choose from. Thermoplastics like Nylon 12 [Versatile Plastic] are extremely popular for a wide range of applications, from drone technology for customers like Quantum-Systems, to a luxury jewelry series of cuff bracelets for Dutch designers Groen & Boothman. All of these companies have used Nylon 12 [Versatile Plastic] for both extensive prototyping to ‘get it just right,’ along with making it the final choice for high-performance, functional products. That does not mean, however, that as longtime customers they haven’t delved into a variety of metals, to include other thermoplastics like MJF Plastic PA12 or precious metals like silver. Along with these materials come a variety of different colors and finishes, along with our latest offering in Nylon 12 [Versatile Plastic] Smooth.

Get to market fast—and effectively

Products that are already in high demand can be 3D printed in customized bulk orders, and for businesses experiencing higher volume in orders, Shapeways recommends that they work with the User Application Team directly for streamlining production and bridging the gap from concept to printability and ultimately, quality manufacturing.

“Our goal is to make the customer experience as seamless as possible,” says Matthew Nadler, User Application Materials Specialist at Shapeways. “We unlock all that Shapeways has to offer for our customers, and enable them to leverage our full capabilities.”

Add-on services are available in manufacturing also, to include product assembly. Shapeways customers like LuxMea have been able to pass on the benefits of customized, on-demand printing and assembly to their own clients as bespoke masks—which include an ergonomic valve system design—are measured to fit with AI software and then completed with a personalized label.

Scale for success

Shapeways 3D prints the masks and also ships them out for LuxMea too, offering total order fulfilment that includes customized packaging for continued brand recognition, along with the opportunity to take advantage of other marketing opportunities at the same time, like adding custom inserts or promotional materials. Shapeways ships orders out to over 160 countries, with bulk pricing available. Proprietary software also makes it easy for other manufacturers to offer 3D printing with fast turnaround, including secure uploading and ordering, instant quotes, and streamlined ordering.

Scaling production is critical to modern businesses of all sizes serving a wide range of applications, and Shapeways is always ready to assist in helping customers grow—whether through 3D printing or other traditional manufacturing methods. In some cases they may begin on the smaller scale with low-batch production in highly customized, 3D printed products and then move on to more traditional methods like injection molding for precise mass production due to customer demand. In other cases, customers may want to navigate manufacturing processes in reverse, or begin employing a hybrid combination of additive and traditional manufacturing.

About Shapeways

Contact Shapeways now to enjoy the benefits of advanced technology and materials for 3D printing creations for the classroom with accuracy, complex detail, and no limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to make over 21 million parts! Read about case studies, find out more about Shapeways solutions, and get instant quotes here.