Edu Fiorin is another one of our $1000 Education Grant winners from the Fall 2016 grant cycle. Hailing from the Universidade Vila Velha in Brazil, Edu wowed us with his proposal for a bespoke protective motorcycle jacket made entirely of 3D printed components. Read on to learn how Shapeways helped expand Edu’s product development process behind the Guardian Jacket. Want Shapeways to sponsor your school project? Fall grant applications are due October 31.

Edu’s concept for the Guardian Jacket came about in response to the significant amount of time modern humans spend on their daily commute. Opting to commute on a motorcycle comes with certain advantages: It’s more economical, often faster, and easier to park — with the added bonus of feeling the wind in your hair. However, wise riders know that motorcycles also necessitate safety gear, which tends to be bulky, super sporty, and an uncomfortable fit.

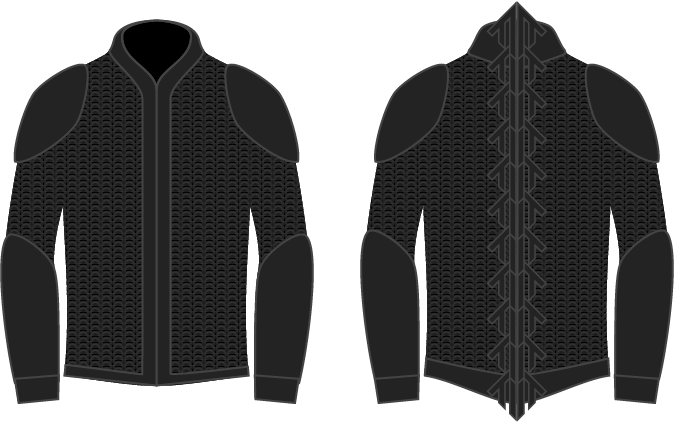

2D Render of the Guardian Jacket

Edu set out to design a safety jacket for the non-professional motorcyclist, and explore the full potential of additive manufacturing by designing and printing every single jacket component, from mesh fabric to closures to hardware. By using the customizable nature of 3D printing to actualize his jacket concept, Edu realized he could offer the wearer a better experience with improved performance, fit, and sustainability.

“The choice of using 3D printing in my design process is also suitable for the production of bespoke goods en masse, sustainably, due to the limited waste generated during manufacturing, and the potential to reduce any carbon footprint related to logistics.”

Aesthetically, the Guardian Jacket is inspired by a combination of bomber jackets and medieval armor:

“It lives between different ages, and our new technology allowed me to achieve this duality by clashing the futuristic with the archaic.”

Functionally, Edu designed the Guardian Jacket to protect the upper body against impact, focusing on spinal cord injury protection.

“The areas with impact reduction will consist of structured parts capable of absorbing applied forces, while keeping the architecture as slim as possible, optimizing the relation between both these qualities.”

“The spinal cord injury protection would consist of a dynamic structure that works as an exoskeleton along the spine on a vertical axis… The shapes that resemble vertebrae would lock into each other, allowing natural movement but restraining wide angle variations.”

Even with all of the Guardian Jacket’s safety functionalities, which would ordinarily add mass to the garment’s silhouette, Edu was able to reach his goal of creating breathable motorcycle gear through the use of 3D printed chainmail — an achievement he chalks up to the power of 3D printing:

“The whole of my project could not have been brought to life without 3D printing – my choice of chainmail-like fabric went almost completely obsolete due to its labor-intensive nature. Now thanks to 3D printing, it’s trending again – machines don’t mind the work. In fact, they go the extra mile, aiding us humans to bring to life our wildest imaginations!”

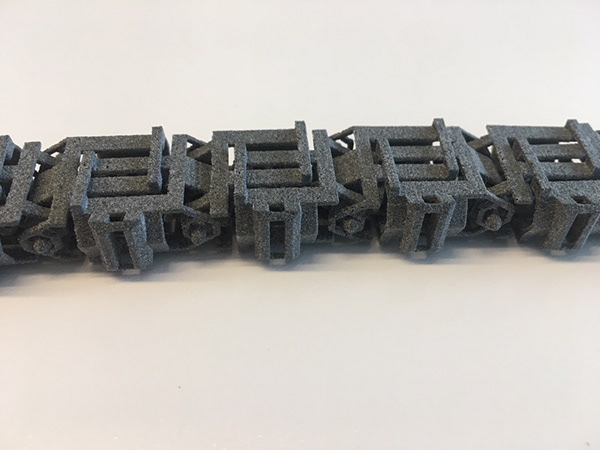

Equally helpful, Edu was able to print perfectly pre-assembled mechanical parts in our lightweight yet durable Metallic Plastic, sparing himself the time and labor of assembly.

A mechanical spring component from the Guardian Jacket, 3D printed in our interlocking Metallic Plastic

We can hardly wait to see the final construction of Edu’s made-to-measure safety jacket, and we are beyond impressed with the en vogue execution of his noble mission.

Do you have an innovative idea that could transform your industry? Let us help bring your ideas to life with 3D printing manufacturing.