Shapeways is excited to announce the launch of three new SLA Plastic materials that provide extreme durability, high resolution and detail as well as a smooth surface.

One of the first 3D printing technologies developed, Stereolithography (SLA) has been widely used for creating models, prototypes and patterns. To produce parts using SLA systems, a laser selectively cures liquid resin in a resin bath above it, moving up layer by layer until the part is complete. Using large format SLA technology, you will be able to produce much larger parts than other resin-based technologies while achieving similar fantastic surface quality.

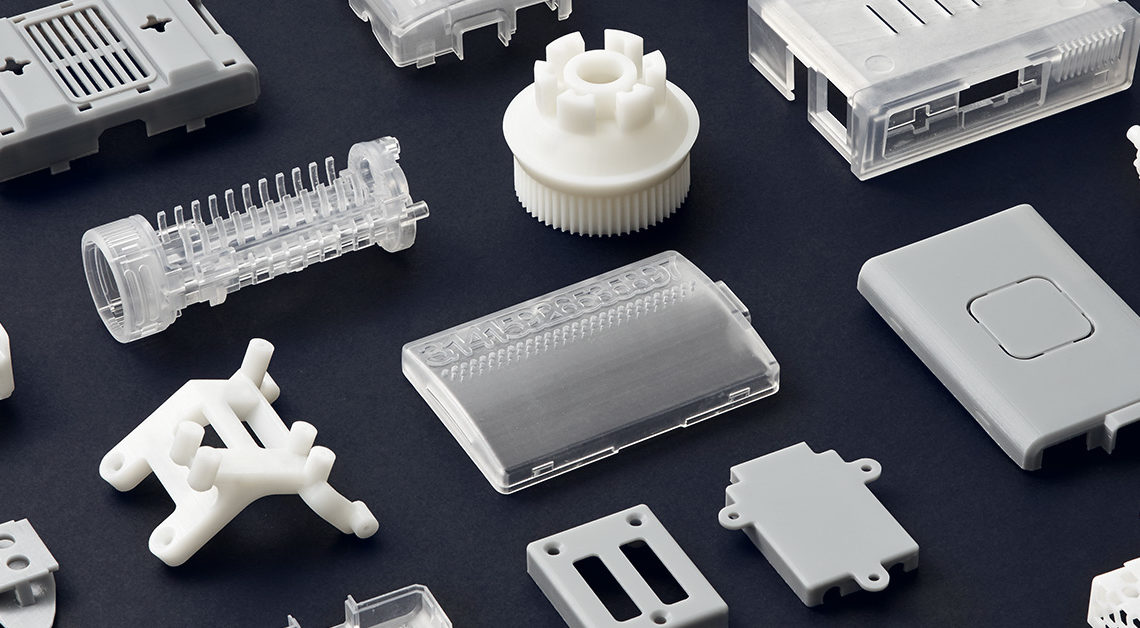

Our SLA Plastic launch includes the following three acrylate-based materials:

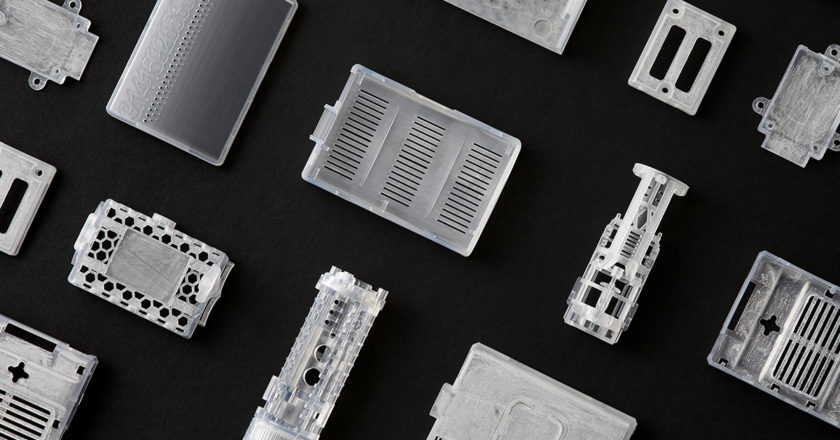

Accura® 60

This clear plastic produces rigid and durable parts with similar properties to molded Polycarbonate (PC). It has the ability for fine details making it apt for tough, functional prototypes, lighting components, medical instruments and fluid flow and visualization models.

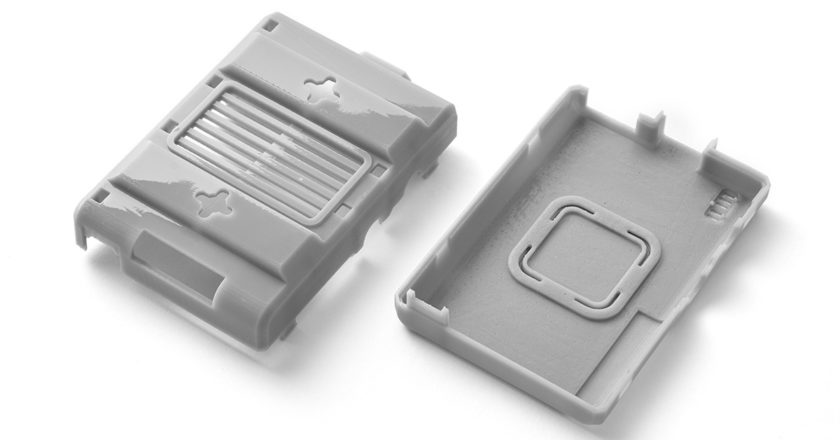

Accura® Xtreme™

A material with similar physical properties to polypropylene and ABS, Accura® Xtreme is an ultra-tough grey plastic with outstanding durability, accuracy, moisture and thermal resistance and the ability for great detail. It is ideal for snap fit assemblies, enclosures for consumer and electronic products, master patterns for vacuum casting, and general purpose prototyping.

Accura® Xtreme™ 200

This white plastic is the toughest SLA material available and can replace CNC-machined polypropylene and ABS articles. It is perfect for projects that must withstand extreme, harsh conditions making it ideal for challenging functional assemblies. It can be applied to similar projects as Accura Xtreme as well projects that demand the highest durability like automotive parts, drill/tap applications, assemblies with self-tapping screws, enclosures for consumer electronic components, general purpose prototyping, and master silicone molding.

All three of these SLA materials produce rigid, robust parts that resist breakage and are durable enough to create functional parts as well as provide excellent detail and accuracy. SLA Plastics are printed on large format 3D printers which is great for creating more sizable parts for visual prototypes, short-run production and mass customization including specific applications such as:

- Master patterns for vacuum casting

- Shell investment casting patterns for metal casting

- Complex assemblies

- Wind tunnel models

- Rapid production of flow test rigs

- Mass customization production (orthodontic, dental)

- Custom assembly jigs and fixtures

These materials have a larger build volume than standard SLA technology, which means your projects will have less limitations. We are excited to see what you create!