Space has been called the final frontier, and it will take more than hardy souls to build settlements amongst the stars. It will require cutting-edge tech, and 3D printing will be essential to that effort. I’ve always found the idea of exploring and colonizing planets alluring. Thanks to 3D printing, the day when humans travel to other worlds is swiftly becoming a reality. From rocket engines to satellites, and habitats to food production, there are very few aspects of space travel that aren’t being transformed by 3D printing.

Made In Space produces the first 3D printer made exclusively for use in, you guessed it, space. Astronauts aboard the International Space Station (ISS) use the Made In Space’s Additive Manufacturing Facility (AMF) for all manner of things. As 3DPrint.com reports, they printed espresso cups for use in microgravity (or zero-G). The AMF has also been used to 3D print a ratchet for use aboard the ISS, and even fiber optics. Made In Space Fiber Optics (MIS Fiber) is especially interesting. While Earth’s gravity causes traditional fiber optics to develop tiny flaws called ‘crystals,’ MIS Fiber, which is produced in space, doesn’t contain these imperfections. This allows for superior data transmission — and the space-made fiber is sent to Earth for terrestrial applications. According to Space.com, the Made In Space printer has also been used to test 3D printing food on the ISS.

This R2 unit, seen at Maker Faire NY, is embellished with 3D printed parts

Building space settlements will not only require additive manufacturing, it will require novel new materials. According to Scientific American, Adam Jakus and his colleagues in Ramille Shah’s lab at Northwestern University are developing a system that utilizes simulated Mars and Moon dust (regolith) inks. The system uses the inks to print rubber-like objects, including LEGO-shaped blocks, which then can be hardened through sintering. The inks were created using a solvent mixture containing an evaporant, surfactant, and plasticiser with regolith simulant powders and the biopolymer polylactide-co-glycolide (PLGA), which acts as an elastomeric binder. The PLGA is made of lactic acid and glycolic acid monomers, which can be found in urine and other biological waste. Recycling will be key to the successful colonization of space.

3D printing is not only being used on the ISS or to build space settlements on Mars. It’s also helping astronauts get there. The Independent reports that RocketLab built the 3D printed Electron rocket. The rocket was printed in 24 hrs. It offers increased performance and efficiency over traditionally built rockets. The rocket launched on May 25th from a private site in New Zealand.

Ultimately, most of those who will colonize other planets are currently in pre-school, so it’s also important to sow the seeds of space wanderlust early. And science fiction has long played a pivotal role in fostering the imaginations of budding scientists. At Maker Faire NY, I (and every kid in sight) spotted one of the iconic characters of the sci-fi classic film Star Wars, R2D2. The R2 Builders Club gave a talk on building replicas of the famous little droid and had some R2D2 and other astromech droids on display at their booth. Much of the bodies of the replicas are made of aluminum, plywood, fiberglass, or other traditional materials and processes. Still, many of the builds were embellished with 3D printed details. If you or your little ones want to start off with a simpler and smaller build, try U.S. Water Robot’s tutorial for a 1/4 scale 3D printed astromech droid.

Open Space Agency’s Ultrascope project

Citizen scientists of all ages can get a jumpstart on exploring the universe by building their own telescope. The Open Space Agency developed an open source Automated Robotic Observatory (ARO) called Ultrascope. The robotic telescope can be controlled with a smartphone and utilizes 3D printed and laser cut parts. Ultrascope plan files and instructions are available on Wevolver.com, an online collection of open source maker projects.

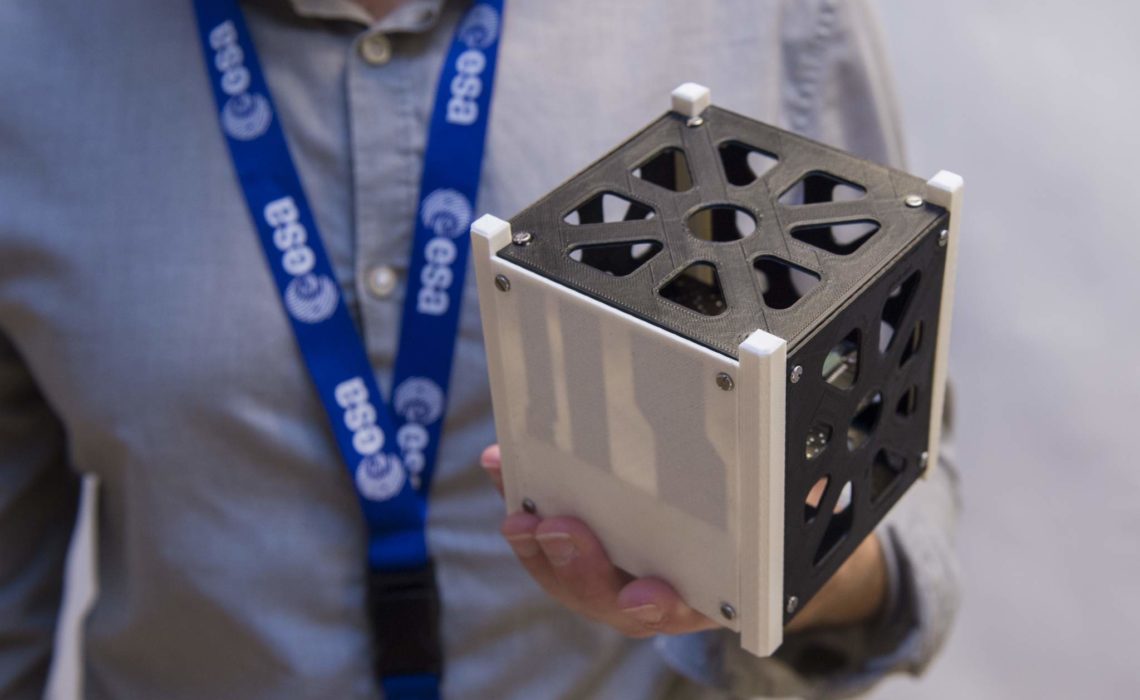

3D printing is making access to space more economical and accessible. 3D Printing Industry reports that the European Space Agency (ESA) is testing out 3D printing the bodies of CubeSats out of PEEK. The 3D printed CubeSats incorporates conductive lines, eliminating the the wire harness typically used to connect CubeSat subsystems. This saves space and weight, and the 3D printed CubeSats can be used by researchers, students or citizen scientists who want to put an experiment into LEO (low Earth orbit).

However we manage to explore strange new worlds, 3D printing will be a key part of how we’ll boldly go where no one has gone before. And in the meantime, it will help open the skies to the amateur explorers, sci-fi dreamers, and ingenious tinkerers who might just come up with the solutions that will get us there.

It is true, R2D2 is very important as an inspiration for future scientists 🙂