What is Metal 3D Printing?

Metal additive manufacturing technology like Binder Jetting, Selective Laser Melting, and Wax Casting make it possible for Shapeways customers to enjoy metal 3D printed parts that are extremely strong, complex, and lightweight.

History of Metal Printing

Metal 3D printing is one of the original additive manufacturing technologies, stemming from development in the late 80’s. Beginning with the work of Carl Deckard in partnership with Dr. Joe Beaman at the University of Texas at Austin, their pioneering efforts began in Selective Laser Sintering–a technology highly associated with powder-based thermoplastics today. At that time, however, Deckard was intrigued by the concept of creating a solution for rapid prototyping and more efficient manufacturing in metal. He realized he could do so by fusing metal particles together and building upon them layer by layer–with the ultimate goal of translating this work to industrial factories.

At the same time, parallel research and development regarding 3D printing with metal was ongoing at the Fraunhofer Institute with Selective Laser Melting–also known as Direct Metal Laser Sintering (DMLS)–and connected with similar technology like Electron Beam Melting (EMB). Binder Jetting was also on the precipice of becoming patented (licensed to ExOne in 1995), offering unique technology built around metal powder particles adhering together with the strength of a liquid binding agent.

Current Trends in 3D Printing Metal

“Increasing adoption of metal 3D printers for the designing and prototyping of products and objects, coupled with the reduced manufacturing expenditure and accuracy in the end product, is a key market proliferating factor. The market is poised to witness high demand arising prominently from the healthcare, automotive, aerospace, and defense sectors. Growing advancements in the healthcare sector to curb physical disabilities and ensure healthy living are influencing the sector to flourish and adopt new innovative methodologies, such as 3D printing. Additionally, the automotive and aerospace sectors, where prototyping and designing play a vital role in research and development to achieve perfection in their production are leading towards greater opportunities and increasing the adoption of the 3D printing process,” states Grand View Research.

“The services segment is expected to expand at a significant CAGR of 23.5% from 2022 to 2030. With the adoption of methodology, metal 3D printing services help manufacturers to produce complicated and delicate functional parts with greater ease and accuracy.”

Purchasing 3D metal printers is extremely cost-prohibitive for most companies, so it makes sense that established metal 3D printing services like Shapeways are projected to continue expanding and contributing substantially to the global market.

Metal 3D Printing Technology and Materials

Binder Jetting Metal 3D Printing

Variables are dependent on the material; for example, in using Steel, there is less shrinkage due to the combination with Bronze. Support materials are not required during printing with either of the metal 3D printers, because surrounding powder acts as a stabilizing force.

Shapeways offers the following metal materials with Binder Jetting:

Stainless Steel 17-4 PH

Shapeways customers rely on Stainless Steel 17-4 PH for industrial manufacturing of:

- Fasteners

- Jigs and fixtures

- Machine tools

- Parts for oil and gas

- Pump components

- Valving

This material is available in silver, with a granular, semi-matte finish that can be polished. Find out more about design guidelines for Stainless Steel 17-4 PH here.

Stainless Steel 316L

Shapeways customers reply on Stainless Steel 316L properties for the following industrial applications:

- Mechanical machinery

- Medical applications like surgical tooling

- Heat exchangers

- Fasteners and brackets

Stainless Steel 316L is available in a natural finish, blasted with ceramic media for a slightly rough surface and a matte finish. It is also offered in a polished finish, with 3D printed parts tumbled for a smooth surface. Find out more about design guidelines for Stainless Steel 316L here.

Steel

This metal is available in the following colors:

- Bronze

- Gold

- Nickel

- Bronzed-Silver

- Black

A matte finish is available for Steel, featuring an unpolished, rough surface. A polished finish is offered for shiny, smooth parts; however, note that parts larger than 150 x 150 x 150 or those with thinner details will be finished with bead blasting instead to avoid breakage. This may also present a rougher, less consistent result. Read more about the design guidelines here.

Selective Laser Melting

During SLM 3D printing, an incredibly precise laser acts as the impetus for welding metal powder particles together within an enclosed industrial 3D printer. Layer by layer, the powder is melted until the desired structure is complete, with the part anchored to the build plate (along with support structures) and removed in post processing. At the end of the process, parts and any supports are removed, and the typically rough surface may be further machined.

Shapeways provides the following 3D printing materials for SLM 3D printing:

Aluminum

Shapeways customers rely on Aluminum for the following industrial applications:

- Aerospace

- Automotive

- Energy

- Machining

- Medical

- Robotics

Shapeways offers Aluminum in Standard finish only. Find out more about the design guidelines for this metal 3D printing material here.

Lost Wax Casting

For designers and engineers eager to try a variation on metal 3D printing technology–but with a fast and more economical edge–Lost Wax Casting is a great option. Paired with high-quality 3D print Lost Wax Casting materials and precious metals this technique is preferred by many Shapeways customers.

Also referred to as Investment Casting, Precision Casting, or even cire perdue (french), this unique technology has historically been recognized as a strong suit for foundries. Created around 5,000 years ago to make metal products and ammunition, Lost Wax Casting is performed in most instances by pouring red-hot, liquid metal into molds to create structures.

Molds for Lost Wax Casting are 3D printed with metal, thermoplastics like Nylon 12 [Versatile Plastic], MJF Plastic PA12, and other materials like Sandstone and Thermoplastic Polyurethan (TPU).

Wax inserts are most often used, structuring the interior of each mold. Once liquid metal is introduced to the mold for making the desired structure, all the wax melts and is drained. With 3D printing, the cooling process is more stable, and once complete, the solidified metal part can be removed. From there, each casting is an exact replication of the previous one. If the mold requires modifications, the design can be changed accordingly, and the part can be 3D printed again easily.

- Brass – An alloy made up of 15% zinc, 5% tin, and 80% copper, Brass is available with a natural matte finish or a shiny polish, and is offered with Gold Plating or Rhodium Plating.

- Bronze – A copper-tin alloy made up of 10% tin and 90% copper, Bronze is used for jewelry with a vintage appearance, featuring a deep red color, marbling, and silver highlights. Bronze materials are available in natural matte or polished finishes.

- Copper – Featuring a red-orange color that oxidizes over time, turning to a deeper color, Copper is desired for its corrosion-resistant properties. This material is available in a natural or polished finish.

- Gold – Both 14-carat and 18-carat gold are available in yellow, white, and rose. Intricate designs can be made for valuable parts or fine jewelry with this precious metal.

- Platinum – One of the highest quality metal materials available, Platinum is a white metal used for luxury products. This material is available in a professional finish.

- Silver – A high-quality alloy, Silver tends to be more malleable, and is popular in the jewelry industry. Silver is offered with the following finishes: natural, polished, fine-detail polished, and antique.

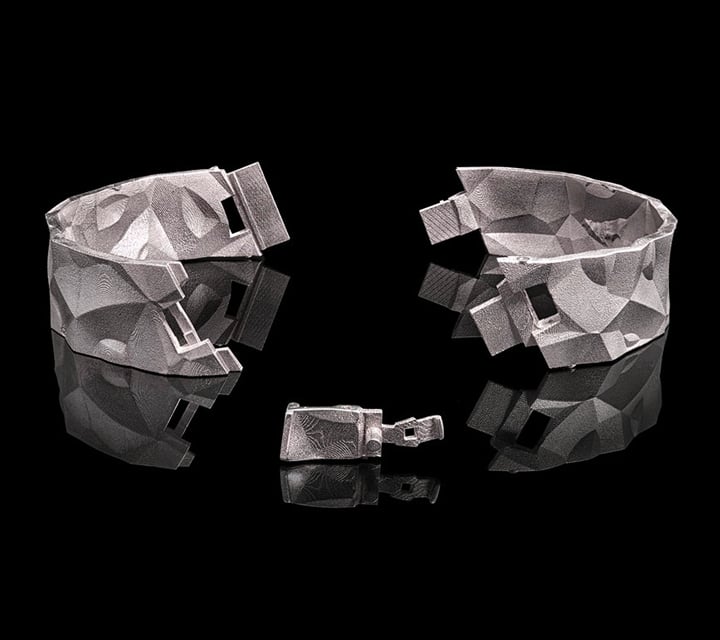

Luxury Sterling Silver Jewelry with Handcrafted Touches

Testimonials

On-demand Metal 3D Printing

Improved efficiency via on-demand manufacturing also allows Shapeways customers to take their metal 3D printed products to market faster. Other great features include:

- Security in uploading 3D models to the digital inventory.

- Large 3D printed parts with reduced assemblies.

- Strong, lightweight parts that are highly optimized for long-term use.

- Less use of resources, materials, and energy.

Shapeways works with businesses of all types and sizes for on-demand metal 3D printing, allowing them to eliminate product backlogs and prevent supply chain issues. Lead times are eliminated, accelerating the prototyping and metal additive manufacturing process, resulting in a more agile supply chain.

3D printing with metal at Shapeways is as easy as uploading a 3D model (up to 20 a once). At that point, an instant quote is activated, along with automated printability analysis. Expedited shipping is available, whether customers need parts shipped to themselves or their own clients.