Over the summer, community manager Ruud van den Muijzenberg and I traveled across Europe visiting RC car events. One of the best things about these trips was the incredibly cool people we met along the way. To our delight, many of them were already using Shapeways 3D printed parts on their RC cars.

At Recon G6 Belgium, a RC scaler and crawler event in the Belgian Ardennes, we were lucky enough to meet Christian Lorenz. He has been using Shapeways to develop his own design of a rock crawler chassis.

Christian and his crawler

Name: Christian Lorenz

Age: 35

From: Karlsruhe, Germany

Profession: Process Operator

Hobbies: Mountain biking, BMX, Running, Swimming

Years in RC: 8

First RC Car: Tamiya Manta Ray

One of the steep, rocky trails at ReconG6 Belgium

Christian made his way from his home in Karlsruhe, Germany to the Belgian forest for Recon G6. He brought multiple cars to the event, but the one we were most interested in is his Prototype Rock Crawler, designed by Christian himself from scratch.

After being out of the RC car hobby for some years, Christian caught the bug again and started with an Axial SCX10 scale truck. While working at a mold-making company, his access to CAD software and milling machines meant that it didn’t take long for him to start making custom parts for his trucks.

Christian’s unnamed Prototype Rock Crawler

The Prototype Rock Crawler is Christian’s second custom build truck. His first project, the Spilux, was a scale rock crawler truck with Pure Spider axles, a custom carbon chassis and a bunch of handmade milled metal parts, all covered by a bobbed Toyota Hilux body. The new crawler was designed to compete in the prototype class in the German Yeti Trial Challenge. Almost every single part on the car was designed by Christian himself and is either 3D printed at Shapeways or milled from carbon fiber plates or brass. It took about three months of development and designing in Cimatron to complete the crawler. It’s an amazing feat of engineering from just one man, one that looks like it’s from a big manufacturer.

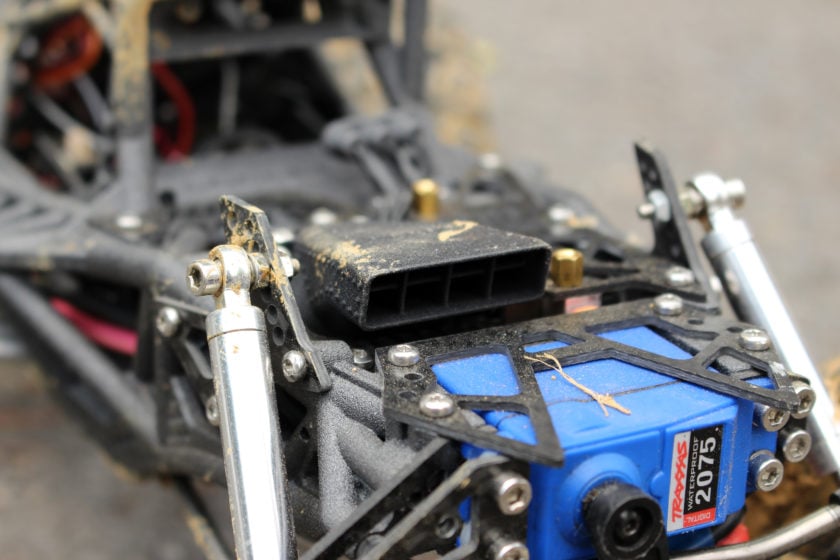

The main chassis is a skeleton construction featuring many extra supports to make sure the chassis is strong and stiff enough to handle the abuse the car will go through. Christian told us he guessed how much support was really needed, and then doubled it just to be safe.

Inside the chassis is a completely custom-made drivetrain. The transmission housing is 3D printed and has steel gears handmade by Christian himself. It also contains a full interior complete with 3D printed racing seat, dashboard, fire extinguisher, and NOS bottle. Even the hood scoop on the front is functional — it has an electric fan inside forcing air onto the motor to keep it cool! Most competition crawlers don’t have any scale details like an interior, but 3D printing makes it possible to fit these components inside the compact chassis and still keep it lightweight.

The car features a fully 3D printed interior

This hood scoop is actually functional and cools the motor

Both front and rear axles are also completely custom-made. They are portal axles, again with steel gears handmade by Christian. He also machined some brass weights for each corner of the car to keep the tires planted on any obstacle. Both front and rear axles have 3D printed housings, but the rear axle is beefed up with a carbon fibre tube inside. This car really is designed to be bulletproof!

Fully custom axles, hubs and even the wheels

The chassis is unnamed at the moment, but at ReconG6 we joked about how it should be called “Skeleton Screamer” because of the way it looks and sounds. Christian powered the crawler with quite an unusual setup combining a regular car’s electronic speed controller with an outrunner brushless motor that’s normally only used in RC airplanes. The result is a small motor with a ton of torque on low RPM and a loud, high-pitched whine, making it sound almost like a turbine engine. The noise is unique to Christian’s car, and really gives it character.

The crawler after conquering the muddy Belgian trails

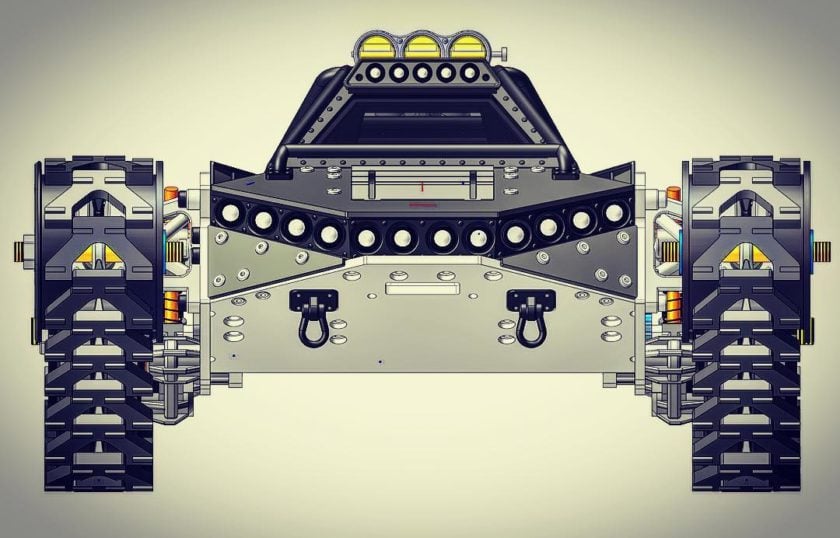

Now, with the Prototype Crawler (AKA Skeleton Screamer) finished — and even taking a podium spot at the Yeti Trial Challenge — we asked Christian what’s next. His current project is even crazier than the crawler: Christian is designing a fully custom-built racing machine on track plates, like a tank, but FAST.

Christian’s new project; A race vehicle on tracks

To follow Christian’s progress, get the first look at his new developments, and keep track of race results, check out his Yoyoyotapilot RC page on Facebook and @Yoyoyotapilot on Instagram.

What’s the craziest car you’ve ever designed?