“Is 3D printing the next industrial revolution, or just hype?”

We get asked this question a lot. The answer, as Peter Weijmarshausen, Shapeways Founder and CEO, has been sharing this past month in talks at SxSW and Inside 3D Printing NYC, and in interviews with Xconomy and 3DPrint.com, is a resounding yes—digital manufacturing will be the third industrial revolution and will change the who, what, where and when of how goods are made.

Until now, several factors have been holding this manufacturing revolution in check: 3D printing needs to be less expensive, have faster turnaround, offer more materials, produce better quality, and print in full color. The very things we hear regularly from you! 3D printing technology has not innovated fast enough to keep up with demand and not at the rate we’ve grown to expect from software. The same 3D printing machines Shapeways started printing on eight years ago still run today, and run as well as new machines on the market.

But that’s about to change.

“The fact [that] we see huge corporations with huge budgets and resources starting to take industrial 3D printing very seriously means that the qualities and capabilities of those machines will start to rapidly evolve, which is exactly what the industry needs,” Pete told Xconomy.

“We also see a lot of money pouring into new startups, which is something I also asked the investment community to do, into companies like Carbon3D, Desktop Metal, and Formlabs. We see big companies and small companies starting to tackle the technology challenges the industry faces. As a result, the end user will get much better products exactly as they want them.”

HP, and possibly Canon, is coming out with new 3D printing technology this year that will be 10-100x faster than current machines. It will print more materials, print them at a fraction of the current cost, and the quality will be significantly higher. Not to mention, they’ll also print in full color.

Combine these innovations with three major trends—the rise of megacities, globalization and digital disruption—and the grounds for an industrial revolution have been set.

Who produces products will shift from major brands that mass manufacture goods based on market research to individuals who will design what they want when they want it or who will work with designers to create what they want.

It will change what gets produced. With the ability to produce goods on demand, the huge investment to mass manufacture disappears and more experimentation can occur. A variety of new products will come into existence—with digital files sent from around the world to be printed locally.

Factories will no longer need to be enormous and located where labor is cheap with products shipped worldwide from these central locations, putting a strain on environmental resources like the crude oil used to fuel container ships. Instead, small factories can be housed in or right outside of major cities, with products customized to suit that city’s needs and culture.

And time to market will be drastically reduced—shrinking from months or years of lead time to research, test and market products to mere days.

We already see this revolution happening at Shapeways, but it’s not real for most people yet. They may be aware of 3D printing, but they haven’t tried it because they don’t see why they should. There are two killer apps evolving this year that, added to the innovations in 3D printing technology, will make 3D printing mainstream.

-

3D scanning—The reaction we’ve seen to being able to create scans of people at parties or of loved ones to send to family members has been overwhelming. There is an instant emotional connection, as well as an intellectual understanding of how a digital file can be turned into a tangible, physical object. With the next generation of phones being equipped with scanners, wide spread adoption is close at hand.

-

Customization—The time and expense needed to make customizing mass produced goods, like sneakers, a good experience has been enormous. We’ve been developing tools, like CustomMaker, that enable people to customize designs on Shapeways, such as adding your name or picture to a product. Since CustomMaker’s launch, over 2,000 customizable products have been added to the site with more being created every day. By opening up product customization on this level, more and more people will expect to be able to put their personal stamp on the items they buy and will seek out 3D printed goods.

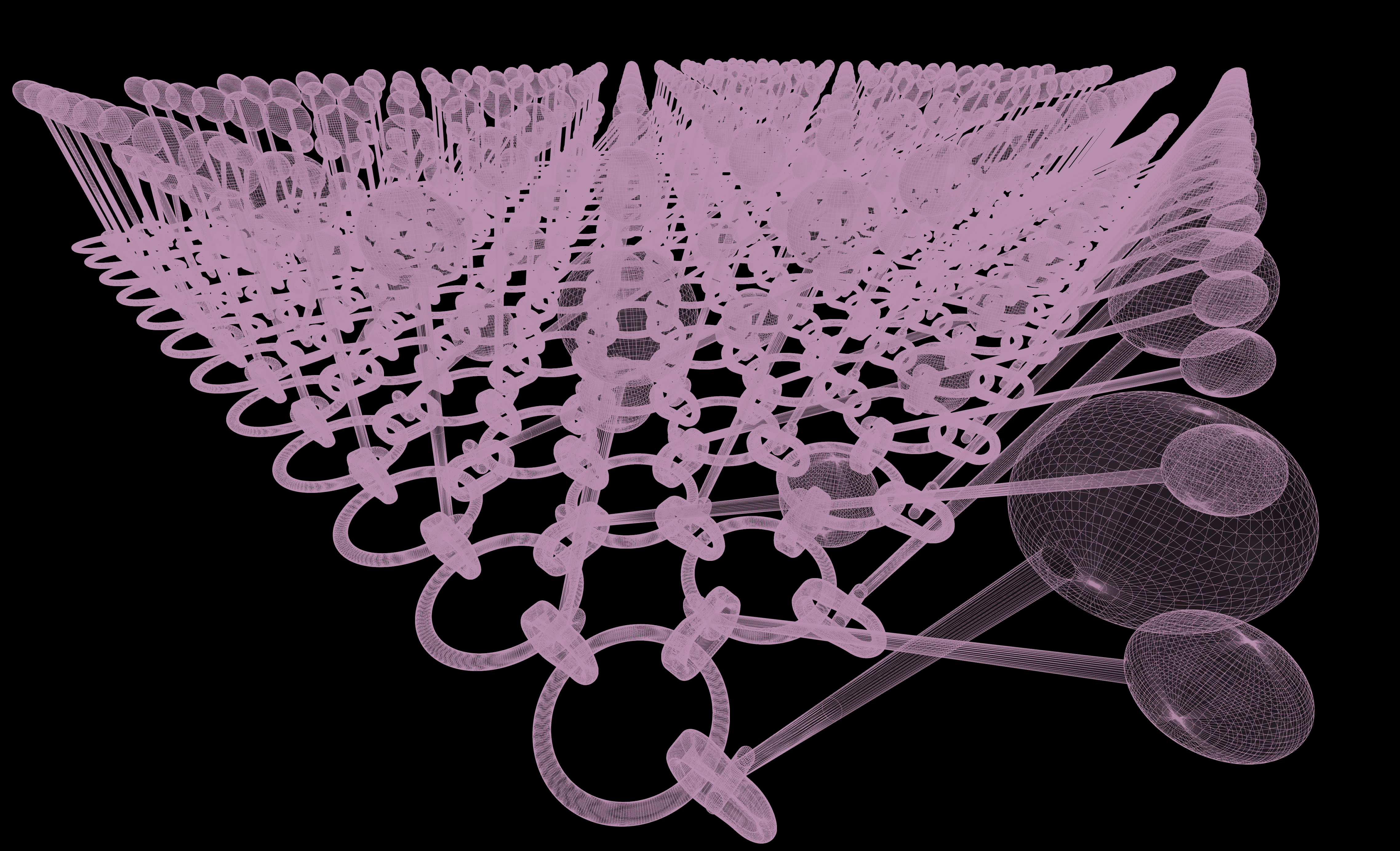

And there is so much more to come. What we make is defined by how it can be assembled, but with the evolution of 3D printing technology and of new materials, how materials and shapes merge will change completely. Even 4D printing could become a reality—where items assemble themselves out of the box due to a reaction with light, or heat, or a chemical being added to it.

As Pete shared with 3DPrint.com, “People have been led to believe that 3D printers as they are today are close to what is possible — I think the opposite is true. We are at early days in this technology. So many things will become possible that people haven’t thought possible, it’s going to revolutionize how we make products.”

To read more about Pete’s keynote at Inside 3D Printing NYC, check out his interviews with 3DPrint.com and Xconomy.

Tell us what you think about the next industrial revolution in the comments, or share your thoughts with Pete on Twitter: @Weijmarshausen.

Yeah, I think it is too. It’s progressing slowly but surely and eventually I feel we will arrive at a threshold where 3D printers can 100% print other 3D printers. When that point comes we will be able to print just about anything that one would find in a typical household with 3D printers that we got for free. We’ll also see industry evolve into printing all things large like ocean going ships and skyscrapers.

I hear you thinking, “Wait… What do you mean free?” Yep! If you have a 3D printer that can print anther 3D printer you’re likely to print one for anyone that wants one for free. Well, minus the cost of materials, which would be trivial. Eventually though, even materials will be free because we’ll design robots that go out and get the materials we want from all over the earth and bring them back to us and other robotic machines will process the materials into whatever particular materials we want. The economies of the world will evolve into a one world economy or a one world order if you will and all humans will thrive because it will be much easier for us to get what we need to live comfortably. Industry will still be intact, but it will evolve into making things too complicated or too large for people to make themselves, supercomputers and skyscrapers for example.

And then, somewhere along this line of time we will see the rise of artificial intelligence. Currently, if you listen you can hear the magnates of the world talking about this. When we arrive at this threshold it will be a change so profound that I cannot even write about it without causing readers to become upset with what I would say. 3D printing will be involved in conjunction with artificial intelligence and things so amazing will occur that science fiction writers will be awestruck. 🙂

Yes. Agreed. However, another way of thinking about this, is not “artificial” intelligence but that our true intelligence will become heightened as we collectively evolve simultaneously with computers.

At that point, we won’t even need 3D printers, because we’ll be the intelligent computers that can analyze data and have mechanical properties that make it possible for us humans, to be the 3D printers.

Actually, technically we already are 3D printers – I wont go into that too much here…. you can PM me for more details…

I’ve been carefully watching the progress of 3D printing and it’s getting very close to meeting my needs but so far it’s falling short. I create silicone puppets for stop motion animation and I would love to be able to sculpt a puppet digitally and print plastic molds. My puppets have texture requirements that must be design specific. From skin textures to smooth shiny characters.

My fantasy would be to be able to sculpt the character digitally and print molds that I can cast the silicone puppets out of. But unfortunately printing the exact texture and tight fitting mold parts falls short. But there may be a good middle ground… I’m waiting for the day you guys begin printing in clay. That way I can have the basic form of the character printed out and then I can manually refine it and make my own molds from it.

I recently saw that there is a company that is producing a sculptable wax/clay blend that can be refined and finished after it’s printed and that would go a long way to saving me time in the sculpting process. (this is the company – http://www.adambeaneindustries.com/ )

That’s my 2¢.

It could be the next political revolution. Tired of being regulated into 3rd world living standards, some people will find a way to print 3D appliances and toilets that actually work. The EPA can sit on it.

This is another facet of the industrial revolution, thanks to printing technologies getting more sophisticated since the late 1980s.

We have the ability to print anything, from fabrics to human organs, from jewelry to artificial limbs. And there is probably no limit to what 3D printing can do.

Anyone want to buy a “just in time” manufactured 3D printed aircraft or vehicle?

They are fast becoming a reality as more vehicle manufacturers are using the technology to print spare parts. It would save billions on storage fees and transportation costs if you could order a vehicle from a local 3D printing facility. Need a replica Shelby Cobra? Done. Want a vintage-looking SPAD or Spitfire using today’s best materials? Done.

Whatever you may want, 3D printing can probably make it for you.

Nice Post! These blogs are a great source of help and also inspiration. Thank you for the post, there are some great sites here.digital media recruitment

Companies like yours providing 3d scaning services.