3D printing in medical applications is, like nearly every other specific industry associated with the technology, expected to grow briskly; in fact recent research projects that the healthcare market 3D printing will reach $5.8 billion by 2030, indicating a growth of over 20% since 2021. Innovation and product development of devices in healthcare covers a wide range of increasingly innovative products–from 3D models and surgical guides to parts that are manufactured for critical medical equipment like Voytek Medical’s industrial cable clasps.

3D Printing in Medical Applications to Make a Difference

Shapeways began working with Voytek in 2015, just as 3D printing was really hitting the mainstream. In creating his 3D printed device for organizing medical equipment, Steven Jaworski, owner of Voytek, was able to garner financial support for his budding business; however, budgeting was critical so he planned to do everything himself. His concept and accompanying design were advanced enough for a hospital to trust in his product and invest, but manufacturing meant finding suitable materials and technology for creating parts strong enough to hold up under rigorous use in a healthcare facility.

The project, and the inception of Voytek Medical, were born out of frustration as Jaworski saw machines continually out of circulation, prematurely diagnosed as broken, when in reality they were just missing a cable. Part of the problem was that one department in need would ‘borrow’ from the other. Jaworski realized that hospitals were losing significant amounts of money every year because medical equipment and cables, quite simply, were not remaining connected as they should have. Even worse, medical personnel were not able to have faith in the equipment they needed to take care of patients. As a biomedical engineering technician, Jaworski realized his days could be much better spent doing much more than just replacing cables. First though, he had an idea, and a design, for locking everything into place.

“That’s the origin story,” says Jaworski, pointing out that, however, that when it came to the idea of using 3D printing in healthcare there was not a dramatic genesis; rather, even though the technology was new to the mainstream public, he had read about it in the media and understood it to be a viable option. Later, the hospital was amenable to his ownership of the intellectual property, and Jaworski had his design patented leaving him to experiment with product development as he saw fit.

On-demand, Industrial 3D Printing is Still Key for Voytek

As Jaworski began searching for options to manufacture his design, he tried a couple of alternative options through different companies, but the materials just weren’t industrial enough for the environment or the rigors of daily life in a healthcare facility.

“3D printers had just become more prevalent,” said Jaworski. “I had not used 3D printing before at all though, and that was my first attempt at CAD. There was a learning curve for sure.”

Difficulties eventually began to arise in terms of industrial needs that his desktop 3D printer simply could not fulfill though. In reaching out to Shapeways, Jaworski was able to create quality prototypes and then move on to manufacturing large volumes of his product.

With the ability to order 3D prints for medical applications on demand from Shapeways, there was no need to have a warehouse to store large volumes of inventory and all profits were put back into Voytek. A ‘menu’ of items was and is ready for customizing and 3D printing at any time, with options in terms of style and color and more for customers to enjoy. Because he was able to order what he needed on-demand, Jaworski was not only able to get the business up and running, but he was able to retain 100 percent ownership without having to go into debt. There were no upfront costs, no tooling costs, and no spending tens of thousands of dollars on molds for larger volumes he wasn’t sure about being able to move.

“The business built the business,” said Jaworski. “I was able to scale as needed, and constantly reinvested back into the company. Any kind of profit went into expanding the product itself, getting better tools, and even better work benches.”

And for the customers, the savings are well worth it–reflected by the growing number of return customers.

The ‘Menu’ of 3D Printed Clasps and Mounts

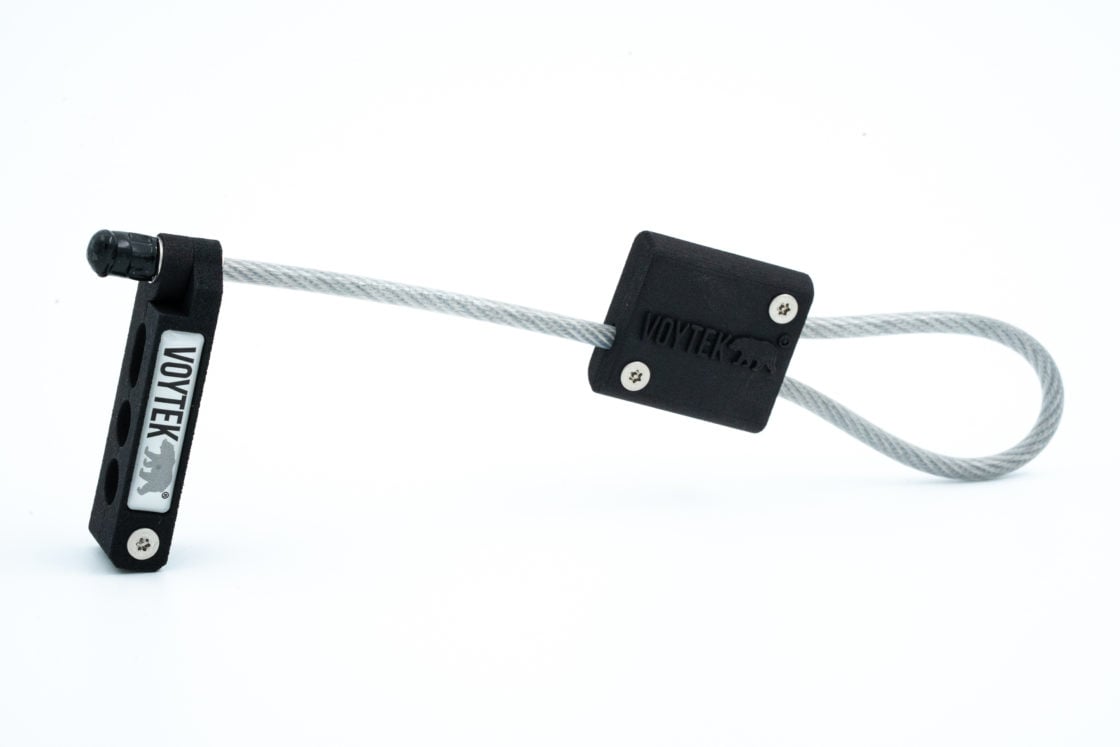

Working from Jaworski’s ‘menu,’ there are several typical clasps that can be 3D printed through Shapeways on-demand. This consists of different orientations, according to Jaworski, whether probes are being ordered for ultrasound machines, bed speakers, or other equipment. The 3D printed clasps featuring three holes are generally used for bedside monitoring operations, while the five-hole clasp is generally used for the ICU in terms of monitoring the patient.

Voytek also produces different types of 3D printed mounts. One might loop against itself, with the wire going through the mount and into the clasp where it screws in. That allows customers to attach it to anything with a handle. Other mounts may screw directly into a wall or any kind of hard surface. Another mount may fit into a standard track.

“Depending on what the order is, for any combination of those, Shapeways gives me the flexibility to order for that part. If a five-hole system is needed for a certain mount, I can just order exactly what I need rather than in bulk,” said Jaworski.

Selective Laser Sintering is used to 3D print all the Voytek products, using Nylon 12 [Versatile Plastic].

“We offer everything in the arsenal that you all have in Versatile Plastic,” said Jaworski, referring to the colors.

The colors are used to distinguish between the departments. This is very effective for identifying the 3D printed clasps from afar, without having to call the clinical engineering team to figure out if they have the right parts.

Each clasp comes with a key to lock it in place, and is designed to work with all medical cables accompanying bedside monitors and roll stands. Voytek Medical products can quickly become indispensable in streamlining the office or hospital environment and even more importantly, these 3D printed products can be used without voiding any product warranties or requiring modifications to expensive equipment.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.