BotFactory began in a Brooklyn apartment, generating a successful Kickstarter campaign in 2015 that raised enough money to produce the Squink. Billed as a ‘personal electronic circuit factory,’ the Squink printed circuit boards (PCBs) from the desktop for engineers impatient to see their ideas come to fruition—allowing them to make anything from drones to watches in mere moments—instead of months.

BotFactory’s insight into what engineers wanted came from their own weary experiences as students at NYU Tandon School of Engineering, where they missed a number of class deadlines while waiting on prototypes. The BotFactory quickly grew from concept to hardware, in the form of their initial machine, the Squink. George Kyriakou, BotFactory co-founder and COO, and his fellow engineers 3D printed the entire circuit board printer in their small headquarters. They were stumped by one part though: the vacuuming mechanism on the pick-and-place toolhead simply was not providing enough sucking action to do its job.

Ultimately, BotFactory realized they needed expert advice in refining the failing toolhead. Shapeways came into the picture upon the advice of a friend, leading them quickly to a new part. It was also the beginning of a great working relationship that has continued for years.

“We started with a very small part,” explained Kyriakou. “Our MakerBot Replicator 2 wasn’t able to make it completely air-proof, and we needed more advanced 3D printing technology for actual part usage.”

Working with Shapeways, BotFactory was able to source materials that worked best for them while making and perfecting the Squink. This was particularly easy due to the proximity of Shapeways in New York City, just a couple blocks away.

In the beginning, BotFactory was extremely happy with the ability to upload models online, find out if there were any printability issues, and best of all, receive instant quotes from Shapeways.

“Back then we were on a very tight budget and we were working with very low numbers, so being able to know exactly what to expect was very important,” said George Kyriakou.

In 2015 as BotFactory reached out to Shapeways for help, they were just beginning to see a glimmer of the future, with an ongoing need for more industrial 3D printed parts—especially with the complex geometries they needed to manufacture. There was also a lot of testing for materials before settling on Nylon 12 [Versatile Plastic] for many of their parts.

As BotFactory has evolved, Kyriakou mentioned the invaluable benefit in being able to work with their own account representative (Kevin Stott) at Shapeways, making the design and production process more helpful than ever as their 3D printing needs expanded.

“Words are not enough!” said Kyriakou in appreciation.

“In the beginning, although [the self-serve option] was very easy to use, as we started scaling up, we needed more. The ability to have an account representative who knows our product and knows our needs has been tremendously helpful.”

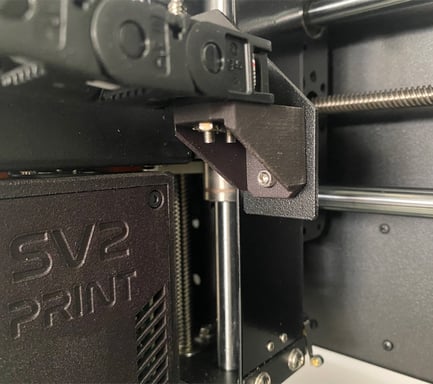

Although they still support their original printer, BotFactory has retired the Squink. Now superseded by the SV2 and an entire range of options to include the Starter, Enhanced, and Professional versions, BotFactory is working with Shapeways to 3D print numerous main hardware components for their circuit board printers. This includes the toolheads for inkjet printing, paste dispensing and pick-and-place—all the main components responsible for performing the fabrication and assembly of a PCB. Shapeways also 3D prints the head casings and other smaller components like mounting brackets.

The entirety of the mechanical engineering was carried out by Lead Mechanical Engineer Pranav Mahamuni, who stated “Shapeways is a key part of our product development cycle—we can count on meeting the strict tolerances and material capabilities that we need to make a precision PCB printer like ours.”

Ultimately, the goal at BotFactory is to create technology so mature and so approachable that they can make it available to every single electrical engineer. In the meantime, they are also working with the U.S. Air Force to develop on-demand 3D printing and assembly of their PCBs.

Check out BotFactory: Engineers Revolutionize PCB Manufacturing with 3D Printing, a case study offering a more in-depth look at how BotFactory grew from a small startup to a sophisticated technology company offering a new series of small circuit board printers.

Engineers from around the world have evolved in tandem with Shapeways, founded in 2007 in the Netherlands and now headquartered in New York City. Shapeways is able to look back on helping many talented individuals and promising businesses get their start in the technology and 3D printing industry—now with over 20 million products 3D printed for more than one million customers.