This month the highly influential Economist Magazine featured 3D printing on the cover along with three articles within exploring the potential changes in manufacturing and medicine brought about by additive manufacturing.

It is an enormous validation of the direction Shapeways is taking to make 3D printing accessible to all when the Economist recognizes that this is a “… a new manufacturing technology will change the world”

Though 3D printing is not new itself, the ease of access to high quality materials and processes with the lowering of cost is recognized as a chief driving factor in the article that mentions Shapeways as part of the revolutionary force. The articles also touch on the speed innovation made possible by the quick iterations, the move from large scale factory to distributed micro production, and with that the change in globalization and labor requirements. Both articles also touch very briefly on the IP complications that are sure to arise with the increased probability of product piracy, but the need not to tighten up legislation to put restrictions that would choke the innovation made possible by the technology. We will cover these points in greater detail over the coming weeks, but it is worth going over these points now briefly, before we delve in deeper.

The Shapeways community has had the pleasure of seeing the the quantity and quality of 3D printing materials available grow over the past few years from polymers to full color, stainless steel and glass all within a couple of short years. As the technologies and the industry surrounding us mature we will continue to push for higher quality, faster processes and cheaper prices to enable the Shapeways community to have access to these benefits as soon as they emerge.

The Shapeways community has had the pleasure of seeing the the quantity and quality of 3D printing materials available grow over the past few years from polymers to full color, stainless steel and glass all within a couple of short years. As the technologies and the industry surrounding us mature we will continue to push for higher quality, faster processes and cheaper prices to enable the Shapeways community to have access to these benefits as soon as they emerge.

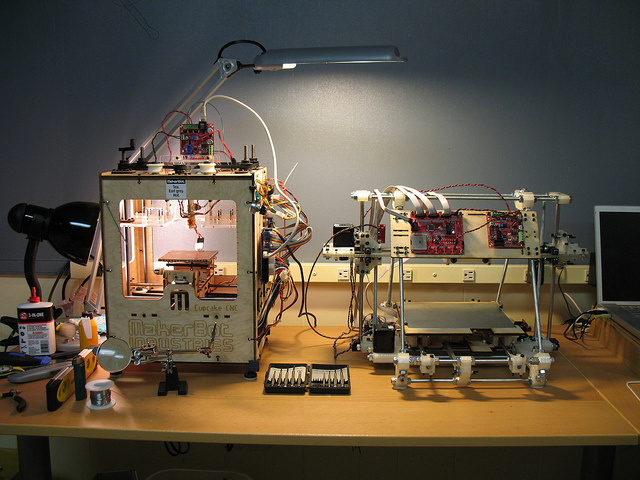

As the current growth continues, additive manufacturing will make production local again, with the distribution of production facilities around the globe and the decrease in cost of materials and processes, the benefit of quantities of scale are reduced and we will head towards an era of personal, not mass production. We are sure to see RepRap and it’s ever-growing family of children like the MakerBot re-reproduce faster, higher resolution and specialised materials (though not simultaneously in the one machine) to take additive manufacture into multiple directions through multiple evolutions.

There will of course be items produced in mass quantities in factories and distributed worldwide, but the ability to make complex changes at little to no additional cost is too attractive not to be increasingly implemented by designers and manufacturers.

Let us know your thoughts and we will continue the discussion over the coming weeks.

“additive manufacturing will make production local again”

for at least 2 billion people (1/3rd of the world), but also many more, production is still ‘local’.

What I find empowering, and what in my opinion will matter more to more people, is that production will be de-centralized for the first time. By taking the specialist knowledge about precision electronics from Japanese know-how, and spreading it in a more accessible way throughout the internet, along with the ability to prototype and produce it anywhere, we are truly on the way to democratize design/manufacturing – ability to make things, experiences and effect change.

Great article! I’m going to read it twice cause it’s just that cool. Here’s to hoping that article and others like it will spark more interest in 3D printing and thus make everyone’s costs lower.

This is how I found Shapeways, now to think what I can do with it all!

Welcome, we look forward to seeing what you do too..

This video has been doing the rounds of the blogosphere over the past few days but for anyone who has missed it so far it is worth checking out. Surgeon Anthony Atala demonstrates an early-stage experiment that could someday solve the organ-donor probl

When Shapeways was featured in the Economist back in February the cover image was of a Stradivarius Violin 3D printed by EOS. Following is a video of ‘In the Meadow’ being performed on the very Stradivarius that inspired the Economist Article