Access to diverse 3D printing materials plays a large role in innovative success, whether designers are rapid prototyping or using additive manufacturing to make high-performance parts. Contributing to a market estimated at over USD $2 million in 2021, demand for 3D printing materials continues to grow. The 3D printing materials market is expected to reach over $8.6 million by 2027, demonstrating a CAGR of 25% through 2027.

Whether customers are designing fine jewelry with handcrafted touches to be cast in precious metal or engineering critical parts for aerospace, Shapeways is dedicated to helping everyone translate their ideas into 3D print.

Matching Compatible Materials with Models for 3D Printing Success

Creating a successful product hinges on bringing together a quality design with the right 3D printing materials and technology. Shapeways makes this endeavor easier than ever with automated printability analysis, activated when a customer uploads a 3D model.

The User Application team is also available to answer questions about potential issues with printing complex geometries–as well as offering assistance with larger 3D printing orders.

“We are there to help with any and all questions about design, materials for the 3D printing, or the processes that make our customers’ models come to life,” says Zach Dillon, User Application Team Lead at Shapeways.

Find out more below about popular materials for 3D printing at Shapeways, including a host of powerful technology options, colors, and finishes.

Nylon 12 [Versatile Plastic] is a 3D Printing Industry Favorite

Shapeways customers choose Nylon 12 [Versatile Plastic] for countless applications, whether 3D printing drone prototypes and then going on to make functional parts with the same materials–or manufacturing critical devices like detailed medical models and colorful 3D printed surgical training platforms.

Aptly named, versatility for this 3D printing nylon material is linked to the combination of Selective Laser Sintering 3D printing and the material’s high ductility, allowing for great flexibility in thinner pieces but a rigid structure with more substantial parts. Featuring other good mechanical properties like tensile strength and abrasion resistance, Nylon 12 [Versatile Plastic] is durable enough to withstand the iteration process, and will hold up over the long term serving in critical applications and even harsh environments.

Expanded design freedom in SLS offers a huge advantage, especially without any need to make support structures. Hundreds or even thousands of parts can be packed into one build via nesting, increasing efficiency while decreasing the potential for damage in post-processing.

Options for Nylon 12 3D Printing Finishes

Shapeways Premium Nylon 12 [Versatile Plastic] offers an upscale finish, elevating designs with a smoother and glossier surface, and resulting in a surface texture that is soft to touch. The Premium finish is recommended for the following:

- Interlocking parts

- Fine jewelry

- Home decor and art pieces

- Accessories like phone cases

Shapeways employs a multi-step tumbling, polishing, and dyeing process to create a consistent color and surface finish, while removing the grainy feel and layered look of 3D printed parts.

Other finishes and colors for Nylon 12 [Versatile Plastic] include:

- Natural – This matte standard finish has a slightly rough surface.

- Processed – Some material is polished away to create a smoother surface.

- Smooth – Offering the smoothest surface, with a slight shine, this finish is attained via vapor smoothing.

- Colors: Versatile Plastic is naturally white. Shapeways also offers Black, Pink, Red, Orange, Yellow, Green, Blue, and Purple.

For Nylon 12 [Versatile Plastic], 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- X + Y + Z ≥ 7.5 mm (Natural)

- X + Y + Z ≥ 25.0 mm and axes must be ≥ 2.5 mm (Processed & Premium)

- 10 x 10 x 10 mm (Smooth)

- Bounding Box Max

- 650 × 350 × 550 mm (Natural White)

- 180 × 230 × 320 mm (Natural & Smooth Black)

- 200 × 150 × 150 mm (Processed & Premium)

- 345 × 375 × 440 mm (Smooth White)

- [Parts over 330 mm long in any direction may have a visible line due to our dual laser printer]

Find out more about the design guidelines for Nylon 12 [Versatile Plastic] here.

Addigy® P3001 is a Strong Performer in Footwear & Sports Protection

Addigy P3001 is another extremely versatile 3D printing material. Offering excellent mechanical properties like good ductility and high elongation at break, this thermoplastic elastomer is made up of both hard (Polyester) and soft (Polyether) segments. Addigy P3001 is popular with manufacturers due to its flexibility for 3D printing interlocking and industrial parts, while consumer goods and apparel companies are drawn to features like high energy return and biocompatibility.

Addigy P3001 meets ISO 10993 standards for biocompatibility, including cytotoxicity. This 3D printing material, regardless of finish, should not cause skin irritation or sensitivity. Because there are no plasticizers like PCBs in Addigy P3001, this material is also suitable for manufacturing toys. Another benefit is easy printability with little to no smoke or odor during production.

This thermoplastic is available in Natural and Smooth glossy finishes in black and white, and is suitable for interlocking parts, seals and gaskets, grips and handles, footwear, and protective gear.

For Addigy P3001, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- X + Y + Z ≥ 15 mm

- Bounding Box Max

- 190 × 190 × 290 mm

Explore the design guidelines for Addigy P3001 here.

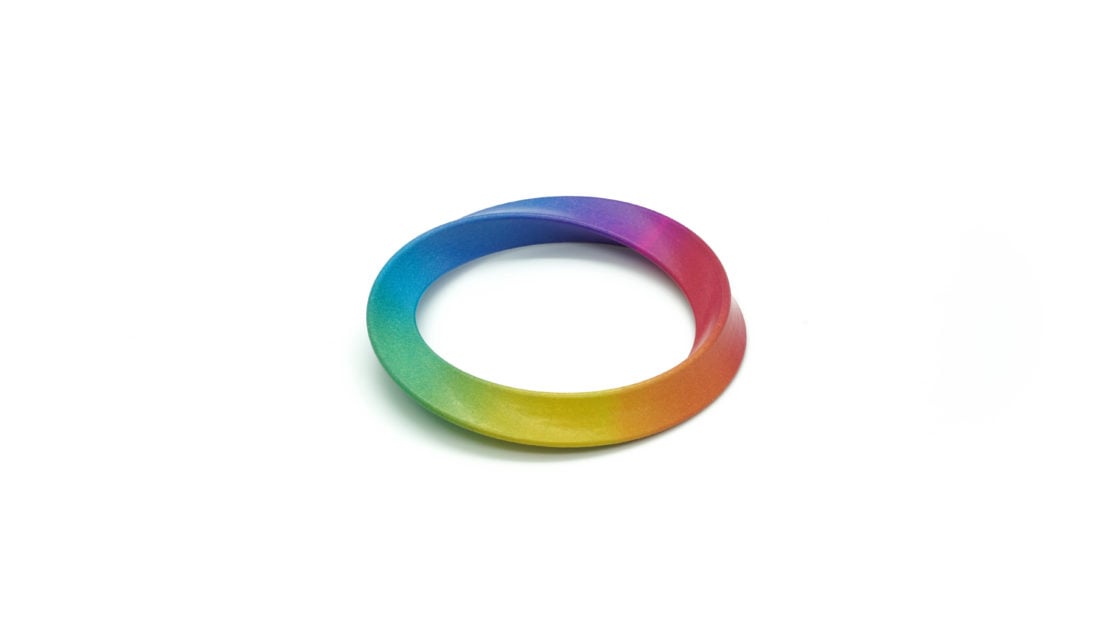

Full Color Materials for 3D Printing

Color plays a vital role in 3D design, offering realism, vibrancy, and elevated style. This holds true in the case of full color 3D printed gaming miniatures, architectural models, and 3D printed medical models. Full color 3D printing may also be chosen for more utilitarian and industrial applications like electronics, where sensors must be different colors to delineate specific uses.

Nylon 12 [Versatile Plastic] is available in an array of colors, but Shapeways also offers more expanded materials for 3D printing with color, to include:

High Definition Full Color is in demand by customers seeking more intense detail, and the ability to choose from ten million colors. The range of 3D print colors includes a full spectrum of eye-popping hues, achieved by using color profiles with specific data for characterization. High Definition Full Color allows for pre-visualization of models, exact color matches, shading, and contrast.

Shapeways High Definition Full Color prints are manufactured on the high-production Mimaki 3DUJ-553, featuring a build size of 508 x 508 x 305 mm. While other color printers offer a variety of benefits, the industrial-grade 3DUJ-553 is founded on Material Jetting (MJ) technology, employing eight unique piezoelectric print heads. Converting mechanical energy into electricity, the printheads deposit liquid photopolymer droplets to be cured with UV light.

Speed and precision, along with the ability to produce robust colors and textures make MJ 3D printing uniquely powerful. While MJ 3D printing is popular for rapid prototyping, this technology is paired with High Definition Full Color for functional models, products, and useful applications.

Most designers choose High Definition Full Color when seeking fine detail with expanded gradients and textures. Designers can use 3D models with thinner walls for more complex designs, even at a minimum of 1 mm, which amounts to the thickness of a credit card.

For High Definition Full Color, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 2.5 x 2.5 x 2.5 mm

- Bounding Box Max

- 495 x 495 x 300 mm

Full-color models produced with High Definition Full Color are available in standard and matte finish.

Find out more about High Definition Full Color 3D design guidelines here.

Nylon 12 in Full Color with Multi Jet Fusion possesses superior mechanical properties, dimensional stability, and good resistance to impact, as well as chemicals like oil and grease. Defined by the capacity to deform under tensile stress, Nylon 12 Full Color (MJF) is flexible for structures with a thinner design but becomes rigid for use with thicker parts, offering the durability and density required for end-use parts.

Manufacturers enjoy greater freedom in engineering and design of parts because (like SLS 3D printing) support structures are not required for MJF 3D printing. As a result, hundreds or even thousands of parts can be nested together in one build, manufactured with accuracy and repeatability every single time.

Operating as a subcategory of powder-based additive manufacturing, Multi Jet Fusion does not rely on a laser for heat or adhesion of the 3D printing layers; instead, this 3D printing technology uses an inkjet array that moves back and forth depositing adhesive agents onto the powder bed, where the nylon particles are melted with thermal heat.

This highly adaptable material is available for Nylon 3D print in Natural and Smooth glossy finishes–suitable for products like jigs and fixtures, braces and casts, interlocking parts, medical models, and prototypes for testing.

For Nylon 12 Full Color Multi Jet Fusion, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 4 x 4 x 1 mm or X + Y + Z > 9 mm (Natural)

- 10 x 10 x 10 mm (Smooth)

- Bounding Box Max

- 130 x 75 x 99 mm

Explore the design guidelines for Nylon 12 Full Color Multi Jet Fusion here.

Heat Resistant Materials for 3D Printing

Using the same materials for prototyping and manufacturing means placing added emphasis on materials like Nylon 11 [PA11(SLS)], especially when seeking heat-resistance, impact-resistance, or corrosion-resistance.

Shapeways offers the following in heat resistant 3D printing materials:Nylon 6 Mineral Filled (PA6MF)

This material is especially well-suited for automotive applications–including 3D printed auto parts in close proximity to the engine. PA6MF is 3D printed with Selective Laser Sintering (SLS) and offers great heat resistance, strength, and stiffness. Filled with mineral reinforcements, this 3D printing material is imbued with enhanced impact resistance, featuring isotropic rigidity and properties similar to injection molded parts without causing added time and expense. Designers and engineers choose materials like PA6MF for 3D printing for structural parts and high-performing, functional prototypes.

The heat deflection temperature for PA6MF is 209°C.

For PA6MF, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- X + Y + Z > 10 mm

- Bounding Box Max

- 375 x 375 x 440 mm

Find out more about this industrial 3D printing material and accompanying design guidelines here.

Nylon 11 [PA11(SLS)] offers durability and heat resistance, 3D printed with Selective Laser Sintering (SLS). Often targeted for use in automotive, aerospace, and drone applications, this material is well-known for its ability to hold up to rigorous conditions like heat and weather. Excellent impact resistance makes this 3D printing material suitable for parts like sports protection equipment. Nylon 11 [PA11(SLS)] is also resistant to a wide range of chemicals.

The heat deflection temperature for this material is 180°C.

For Nylon 11 [PA11(SLS)], 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 0.7 × 0.7 × 0.7 mm

- X + Y + Z ≥ 7.5 mm

- Bounding Box Max

- 200 × 200 × 300 mm

Find out more about Nylon 11 [PA11(SLS)] and accompanying design guidelines here.

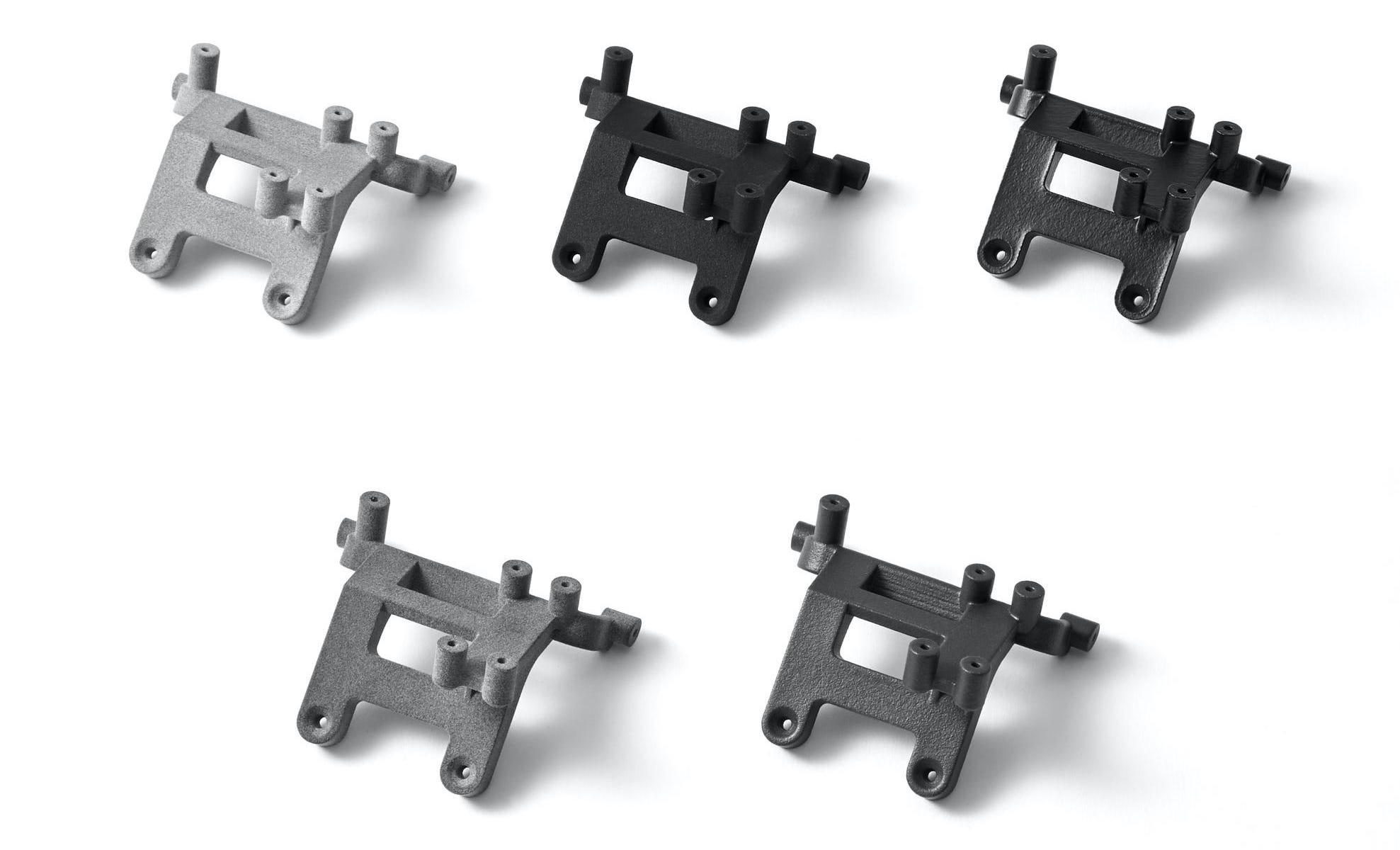

MJF Plastic PA12 is 3D printed with Multi Jet Fusion. A heat-resistant thermoplastic meant to support complex geometries and detailed parts, MJF Plastic PA12 is in demand for dimensionally accurate products with finely tuned mechanical properties. This material offers great strength, durability, and stiffness. Suited for a wide range of applications, MJF PA12 is 3D printed for durable end-use goods, including high-performance industrial parts, smaller components like mounts, brackets, and consumer goods.

The heat deflection temperature for MJF Plastic PA12 is 95°C. For this material, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 4 x 4 x 1 mm or X + Y + Z > 9 mm (Gray and Black Natural)

- 10 x 10 x 10 mm (Smooth)

- Bounding Box Max

- 284 x 380 x 380 mm (Gray Natural and Black Smooth)

- 210 x 210 x 360 mm (Black Natural)

Note: Parts covering the exact maximum bounding box dimensions might not be printable due to printer limitations.

Find out more about this popular 3D printing material and accompanying design guidelines here.

MJF PA12 Glass Beads (MJF PA12GB)

3D printed with Multi Jet Fusion, MJF PA12GB is an excellent choice for applications like large, flat parts that may be prone to warping with other materials. This material is suitable for high-performing 3D printed parts that require high strength and dimensional accuracy. Engineers rely on MJF PA12GB for 3D printing robotics, drones, medical, housings and cases, and tooling.

The heat deflection temperature for MJF PA12GB is 114°C. For this material, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 4 x 4 x 1 mm or X + Y + Z > 9 mm

- Bounding Box Max

- 284 x 380 x 380 mm

Note: Parts covering the exact maximum bounding box dimensions might not be printable due to printer limitations.

Find out more about this popular 3D printing material and accompanying design guidelines here.

Aluminum – Relying on Selective Laser Melting (SLM) technology, Aluminum alloy AlSi10Mg provides good heat resistance, as well as offering a lightweight material that is strong, durable, and accurate. This Aluminum 3D printing material provides excellent corrosion resistance, high electrical, and thermal conductivity. 3D printed Aluminum can be machined, milled, and tapped, making it ideal for outdoor applications.

The heat deflection temperature for Aluminum 3D printing material is 570° C. For this material, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- X + Y + Z > 30 mm

- Bounding Box Max

- 250 x 250 x 200 mm

Find out more about this material for 3D printing and explore the accompanying design guidelines here.

Stainless Steel 316L – This extremely heat-resistant metal is 3D printed with Binder Jetting technology. Offering excellence in corrosion resistance and tensile strength, this metal 3D printing material is a single alloy, 100% Stainless Steel. Shapeways customers rely on Stainless Steel 316L for 3D printing mechanical machinery and parts like heat exchanges, fasteners and brackets, and surgical tooling for medical applications.

The heat deflection temperature for this metal 3D printing material is 1375-1400° C. For Stainless Steel 316L, 3D models must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 15 × 7.5 × 3 mm

- Bounding Box Max

- 127 × 127 × 76.2 mm

Find out more about this popular metal 3D printing material and accompanying design guidelines here.

3D Printing Precious Metals with Wax Casting

Wax casting is a multi-faceted process for creating metal parts that has been in use for thousands of years, requiring expertise and sophisticated tools. At Shapeways, this technique includes 3D printing molds which are injected with molten metal.

With the ability to 3D print any type of complex mold, this modern twist to wax casting allows for unique master patterns to be easily customized and manufactured, adding sprues so that metal materials flow through after the initial wax has melted and drained. Metal structures detach easily from the plaster molds and can then be tumbled for polishing.

At Shapeways, this type of manufacturing is used for making prototypes, home decor, jewelry, and marine accessories. Wax casting allows for superb finishing, while metals like Copper offer good corrosion resistance.

Following are precious metals for Wax Casting:

Bronze is a Copper-Tin alloy made of 10% Tin and 90% Copper. This material is often used for jewelry with a vintage appearance, featuring a deep red color, marbling, and silver highlights. Bronze jewelry at Shapeways is made via Wax Casting, and is suitable for bracelets, earrings, and cufflinks—all available in natural matte or polished finishes.

For Bronze, designs must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 2.4 × 2.4 × 0.6 mm

- Bounding Box Max

- 89 × 89 × 100 mm

- 75 × 75 × 40 mm for interlocking parts

Find out more about this popular 3D printing material for jewelry and accompanying design guidelines here.

Brass – An alloy made of 15% Zinc, 5% Tin and 80% Copper, Brass is popular for jewelry designs requiring intricate detail in manufacturing. Made via Wax Casting, Brass jewelry from Shapeways is available with a natural matte finish or a shiny polish.

For Brass Wax Casting, designs must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 2.4 × 2.4 × 0.6 mm

- Bounding Box Max

- 89 × 89 × 100 mm

- 75 × 75 × 40 mm for interlocking parts

Find out more about Brass and accompanying design guidelines here.

Gold is another precious metal from Shapeways. Both 14K and 18K gold are available in yellow, white, and rose. Gold is one of the highest quality materials Shapeways offers. Capable of showcasing intricate details, Gold offers a professional, finished look.

For Gold, designs must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 2.4 × 2.4 × 0.6 mm

- Bounding Box Max

- 89 × 89 × 100 mm

Find out more about Gold for making jewelry, and view accompanying design guidelines here.

Platinum is one of the highest quality materials available. A white metal used for high-end men and women’s jewelry, Platinum products like cufflinks, tie bars, rings, bracelets, and necklaces are made via Wax Casting.

For Platinum, designs must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 2.4 × 2.4 × 0.6 mm

- Bounding Box Max

- 89 × 89 × 100 mm

Find out more about Platinum for making jewelry, and view accompanying design guidelines here.

Silver is a high-quality alloy used with Wax Casting to make cufflinks, tie bars, rings, bracelets, and pendants. This metal tends to be more malleable and is always a favorite for jewelry makers. Shapeways offers Silver with the following finishes: natural, polished, fine-detail polished, and antique.

For Silver, designs must meet the following minimum and maximum bounding box sizes:

- Bounding Box Min

- 2.4 × 2.4 × 0.6 mm

- Bounding Box Max

- 89 × 89 × 100 mm

- 75 × 75 × 40 mm for interlocking parts

Find out more about this material and view accompanying design guidelines here.

Shapeways offers over 90 materials and finishes. We are also willing to source additional products when possible due to unusual 3D printing project requirements.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.