While as of the time of writing, the air travel industry is facing significant difficulties in the face of pandemic-driven reductions in flights, for many years aircraft have been proving one of the fastest-growing applications for 3D printing around the world. We expect that air travel will resume in the not-too-distant future — and that will see demand for state-of-the-art aircraft on the rise. Some manufacturers may even be using this unanticipated downtime to revamp their fleets, building up digital inventories to supply aging aircraft and using advanced manufacturing technologies to create the next generations of aircraft.

Let’s dive in to find out just why the aircraft industry is using 3D printing.

A Fit For 3D Printing

Aerospace is a unique fit for many of the most-touted benefits of 3D printing:

- Part consolidation

- Lightweighting

- Complex geometries (“freedom of design”)

- Rapid prototyping

- Low-volume production

- Digital inventory

Let’s look at each of these areas to see how the production of aircraft can make use of these benefits.

Part Consolidation

The weakest point in an assembly is where it has been, well, assembled. When it comes to aircraft, such a weakness could become a point of critical failure, endangering human lives.

By consolidating multiple components of a part into a single 3D printed build, the number of assembly points is necessarily reduced. The unique geometries possible with 3D printing can reduce a part that typically has dozens or hundreds of parts to few — or to one single part. With no welding, riveting, or other fastening needed to keep the part together, not only are SKUs reduced, but so too are potential points of failure.

Lightweighting

Every ounce of weight matters when it comes to equipment meant to fly. Lighter-weight parts means less fuel, improving not only the carbon footprint of a flight but also the cost to fly.

Materials innovations in 3D printing are seeing constant improvements in different metals and polymers approved for use in different equipment. Many of these engineering-grade materials are familiar to those who have worked with them in traditional manufacturing — translating these formulations into 3D printable materials is bringing their capabilities together with part consolidation and other time- and material-reducing benefits to create altogether lighter final parts.

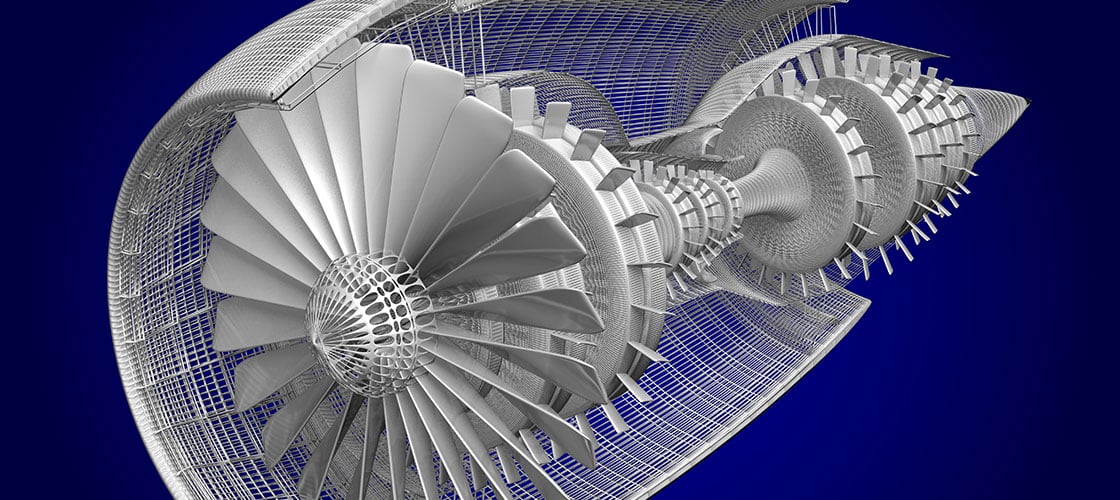

Freedom of Design

Many working with design for additive manufacturing (DfAM) like to proclaim that the technology offers great “freedom of design,” as complex geometries impossible to make with other manufacturing processes are for the first time possible.

Design methods like topology optimization and generative design are developing new shapes never before dreamed of that can be created only by 3D printing. These complex, often lattice-like designs not only reduce weight by including material only where necessary, but are often stronger than legacy designs. While certain constraints of course still exist, and may vary by 3D printing technology and material used, these are in many ways significantly reduced from those seen in traditional, subtractive manufacturing processes. New interior and exterior aircraft components can be designed to replace stodgy original parts, adding both design finesse and extreme functionality.

Rapid Prototyping

The earliest use of 3D printing is also its original nomenclature: rapid prototyping.

Quickly going from a napkin sketch idea to a CAD design to a first prototype — and then a second, third, and so on — speeds up the time-to-market for new products. While traditional manufacturing may require multiple iterations to be sent back and forth over weeks or months, the fast-paced aircraft industry can see much faster turnaround when designs can be created and finalized within days or weeks.

Low-Volume Production

As large as the aerospace industry is, by total volume the sheer number of aircraft produced is relatively small compared to, say, automotive or appliance production.

High-value, low-volume production is a perfect fit for 3D printing. Whereas many traditional manufacturing processes require expensive tooling and molding to be made, creating economies of scale for mass production, no molding is necessary for additive manufacturing. One or a few pieces may be made at a time — including different designs on the same build plate — with no additional molding or tooling costs. The point of inflection for additive versus traditional manufacturing typically requires hundreds or thousands of parts to be made before traditional techniques are more cost-effective — and while that may ultimately reduce costs to pennies per injection molded part, before that crossover point, 3D printing is more cost-effective. This is especially the case when using high-value metal powders, when material savings are imperative; 3D printing eliminates significant waste of material as only the material needed for a given build need be used, and much else can be recycled, rather than cutting away and wasting material from solid blocks in subtractive manufacturing processes.

Digital Inventory

When an aircraft is approaching the end of its useful life, often it can be salvaged through replacing certain parts to keep it flying. This is often done through use of physical warehouses, where these spare parts were stored on shelves until needed. These spare parts, in most cases, were made at the same time as the original mass-produced OEM parts, set aside to await replacement demand for worn parts. If that demand never comes, though, they were a waste of not only the time and cost of producing them, but also of storing them on shelves for however many years. Worse, if that demand comes but spares are out of stock — especially those forever out of production — the lack of a small part may ground a plane.

Rather than physically keeping goods on shelves, digital fabrication methods allow for storage of a design file that can be 3D printed on demand. 3D printing a replacement part allows for only those parts needed to ever be made — again without need for first producing costly molding or tooling. These on-demand spare parts can also be made anywhere with the appropriate technology, rather than awaiting OEM delays that can all too easily run up into weeks or months.

Flying High With 3D Printing

The production of aircraft, from prototype to spare parts, is increasingly benefitting from the use of 3D printing in the supply chain. Decentralized production, new design possibilities, and reductions in time, materials, and costs are offering new ways for aircraft to keep flying high.