When it comes to application-specific 3D printing, the medical industry presents unique challenges and benefits. Few other areas of manufacturing touch human lives in quite the same way, as the production of medical products directly impacts the quality of life.

3D printing is increasingly coming into use as a valid — and, importantly, validated — solution for the production of medical products. What can be made today, and how are those whose lives could benefit from these products able to gain access to them?

Immediate-Need Medical Supplies

One of the most critical 3D printing applications of the moment is the production of urgently needed medical supplies including personal protective equipment (PPE). Supply shortages are impacting medical personnel on the front lines of the fight against the spread of novel coronavirus as COVID-19 cases pick up around the world. 3D printing is proving its value in immediate-need PPE such as face shields, able to provide a stop-gap solution as traditional supply chains pick up. Shapeways is among the manufacturing agencies qualifying as an “essential business” during this pandemic, and is working constantly to produce necessary equipment. Read more about Shapeways’ response to and resources for COVID-19 here.

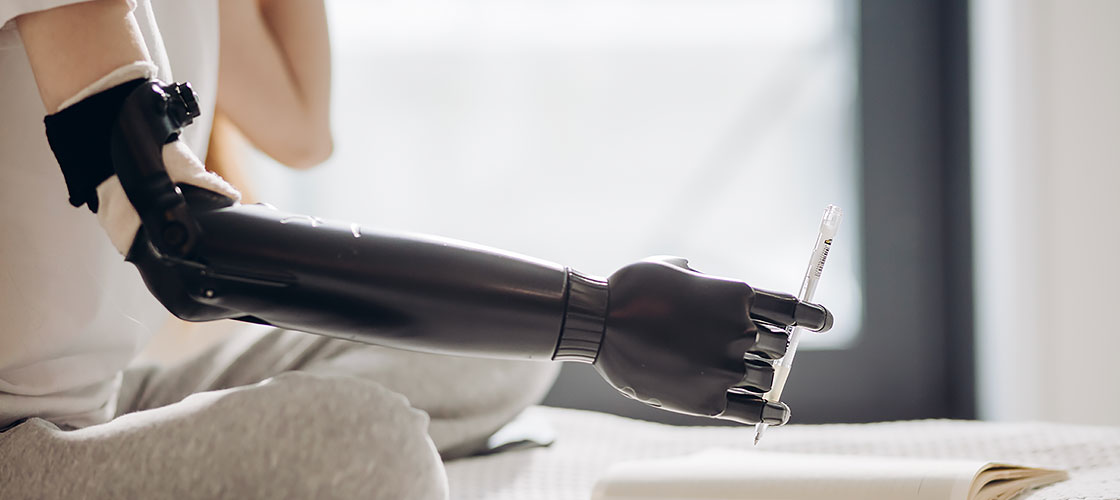

Patient-Specific Orthoses & Prostheses

Products that assist in individual mobility are much more effective when they are made for that individual. 3D printing offers the ability for manufacturers to create orthoses and prostheses that are fully personalized to fit not only the needs, but the exact anatomy of each individual. Braces, orthotics, and prosthetic limbs can all be 3D printed in durable materials to perform in real-world day-to-day life. When created through a trustworthy supplier, such devices will have been optimized with functional integration and tested in simulations and mechanical methods. Shapeways, for example, offers a market-ready solution for these uses made using EOS 3D printing technology with Nylon PA11 material. This PA11 material offers key benefits such as high elongation at break, elasticity, and high impact resistance.

Medical Devices

Medical devices including eyewear, implants, hearing aids, and surgical instruments can be 3D printed for prototyping, modifying, and completely customizing products. Rapid prototyping is speeding the time-to-market process for new products, as the latest 3D printing technologies allow for different needs during different parts of the design process. When speed is of the essence during iterative design, 3D printing can quickly produce new prototypes to get a hands-on feel for new designs and measurements. Later in the design process, realistic full-color 3D printing can produce parts that look just like the final product will. These medical devices can also be modified to suit individual or rising needs, or fully customize parts for an individual. Hearing aids, for example, are nearly all 3D printed these days, as these small devices can be made to exactly fit the wearer’s unique ear anatomy.

Surgical Tools & Guides

3D printed surgical tools and guides can be made using sterilizable materials for use directly in the operating theatre. Surgical guides can be fully personalized to fit the exact anatomy of a patient, showing surgeons exactly where to focus during an operation, saving precious time and increasing accuracy during procedures. Advances in materials science have enabled the 3D printing of tools that can be fully sterilized and safe for human contact.

Educational, Training, & Surgical Planning Models

3D printed models aren’t just for show, as medical professionals can produce patient-specific anatomies for hands-on understanding. The human mind thinks best in three dimensions, and holding an exact replica of anatomy can help a patient understand exactly what will happen during a medical procedure. Surgeons and other medical professionals can use such models to practice ahead of complex procedures, reducing time needed in the operating room and so saving the patient procedure time — encouraging faster recovery — as well as reducing the expense of running an OR. New doctors can also train in new procedures using 3D printed models that look and feel just like the real thing. Full-color, multi-material 3D printing such as with the Stratasys J750 3D printer can produce results that are astonishingly close to real life.

Medical Models

Biologic Models

3D printing can also scale up structures for hands-on understanding. 3D printed small molecules; proteins, macromolecules, and viruses; and bacteria, cells, tissues, and other organisms can be created from digital files for scaled-up, hands-on learning and training that could not be achieved on a screen. Students of many ages, from grade school to medical student and beyond, can gain better understanding of the world around us — and the pieces that comprise it.

Bioprinting

Perhaps the pinnacle of medical 3D printing is bioprinting. In this application, living cells and tissues are 3D printed to create new structures capable of life. Often created with cellular scaffolds, tissues of organs such as the skin, liver, and kidney have been successfully 3D printed for research, drug and cosmetic testing, and even early transplant efforts. The ultimate — and still years-ahead — goal for bioprinting is to provide lab-made organs for people waiting on the organ transplant list, helping to save lives.

Offering end-to-end 3D printing manufacturing and fulfillment services to 130 countries, Shapeways offers a base to start the medical 3D printing journey. Find out more about Shapeways’ medical 3D printing offerings here.