Shapeways Custom 3D Printing: What is Rapid Prototyping?

Prototyping is an essential step in the product development process for manufacturers intent on taking quality goods to market. While Shapeways customers may design only a handful of rapid prototypes manufactured with our custom 3D printed rapid prototyping services, others may 3D print hundreds of test parts. The rapid prototyping process often includes testing a variety of 3D printing materials, additive manufacturing technologies, colors, finishes, and more. While developing parts, testing, and implementing feedback, manufacturers can easily modify any 3D design with just the click of a button.

The History of Rapid Prototyping

3D Printing is the original rapid prototyping process. Chuck Hull patented the technology in 1984, going on to found 3D Systems in 1986, and receiving the The Economist Innovation Award in 2013 for his life’s work. In creating Stereolithography, Hull endeavored to accelerate the product development process, moving away from lengthy wait times during each stage of the design process. Even Hull is known to have been pretty surprised about the evolution of 3D printing though:

“I always knew that 3D printing had the capacity to significantly change the entire design-to-manufacturing process, but greatly underestimated the full impact that my work would have on every facet of our lives,” said Hull, who has explained that in developing Stereolithography (SLA) 3D printing, he was always thinking in terms of design engineers.

Hull created the term Stereolithography in his August 8, 1984 patent application for the ‘Apparatus for production of three-dimensional objects by stereolithography.’ Centered around a concentrated beam of UV light focusing on a resin-filled vat, SLA works as the laser beam traces the shape of each structure on the top of the liquid, curing and solidifying each subsequent layer with heat. SLA 3D printing for rapid prototyping continues to serve its original purpose–and far beyond–making it possible for engineers to create prototypes quickly and allow industrial users to manufacture durable, functional parts with high resolution and tight tolerances.

The Different Types of Rapid Prototyping

The product development cycle includes the need for physical prototypes at several stages of design including:

- Concept

- Assembly / Fit

- Function

- Testing

When 3D printing–from prototype to final production–the same technology can be used throughout the product development cycle. That does not, however, mean that the same materials are necessarily the best choice at every step. Early stages of prototyping may focus on speed and a rough concept rather than on final quality. Inexpensive plastics are often the best fit at first, especially when 3D printing several iterations in quick succession. Each refinement in the prototype process may call for a better-quality material, and staging material selections can help cut costs, keeping the finer-detail options for later-stage planning. Following are examples of typical 3D printed prototypes:

Simple, economical 3D printed prototypes – Parts may be manufactured through our 3D printing prototype service using materials like Sandstone. Common for preliminary architectural models not meant for extensive handling, basic prototypes mark the beginning of product development. Basic 3D printed models may also be used for educational purposes, a variety of presentations, and concept testing.

3D printed display models – Architectural visualizations 3D printed in model form are a great example of this type of prototype. While they may be used during project development or displayed during a presentation, models manufactured through our 3D printing prototype service may become permanent displays encased for longevity. An excellent use case exemplifying this type of model would be The Village. Tapperworks partnered with Shapeways to print a 3D printed architectural scale model featuring 94 apartments and five towers. Created as a permanent display, The Village was printed with a variety of 3D printing technologies and materials, to include Fine Detail Plastic, High Definition Full Color, and Sandstone.

Functional prototypes – Usually 3D printed to test for form and fit, functional prototypes vary in timespan for use. For automotive, aerospace, and drone applications, 3D printed functional prototypes are critical to creating quality parts that are just right before final production, whether using additive manufacturing or traditional manufacturing like Injection Molding. Quantum-Systems serves as a great use case, not only saving tens of thousands of dollars through prototyping with materials like Nylon 12 [Versatile Plastic] and MJF Plastic PA12, but also in using those same 3D printing materials for functional, end-use parts like electronics housings.

3D printing these different iterations offers all the benefits of digital manufacturing–from speed, agility, and lowered costs for one-off production–to every stage of product development.

Rapid Prototyping: 3D Printing Materials and Technology

SLA parts can be 3D printed on the small or large scale with precise, complex geometries. Shapeways offers a variety of Accura® SLA materials for projects requiring strength and accuracy, good surface finish, and watertight properties.

Accura 60 is a translucent, acrylate-based plastic suited for challenging functional assemblies that require transparency. This material offers excellent clarity and high rigidity.

Accura Xtreme™ is a gray acrylate offering good impact resistance, and is recommended for 3D printing complex, functional parts.

Accura Xtreme™ 200 is a white acrylate, set apart by ultra-tough mechanical properties, and known for resisting breakage.

MJF Plastic PA12 with Multi Jet Fusion 3D Printing

MJF Plastic PA12 is another popular 3D printing material for prototyping and end-use manufacturing. Similar to Nylon 12 [Versatile Plastic] in material form, Shapeways 3D prints MJF PA12 with Multi Jet Fusion technology—a powder-based method relying on inkjet technology. MJF PA12 is unique because it is printed at a lower layer thickness, provides higher resolution for intricate features, and overall uniformity.

MJF PA12 offers flexibility in its thinner material form and is known for greater elasticity and less breakage, while offering strength and durability for thicker designs. Offered in gray or black with a slightly grainy finish, MJF PA12 is available in Natural, Smooth, and a slightly glossy finish. Find out more in the design guidelines here.

MJF Plastic PA12 Glass Beads is a unique material, employing glass beads to add strength and stiffness to prototypes and end-use parts. Although 40% of this material is infused with glass beads, MFJ PA12GB still offers good flexibility like its MJF PA12 counterpart. Designers rely on PA12 Glass Beads to ensure structural integrity and dimensional accuracy for industrial parts, along with repeatability whether 3D printing parts at volume or printing on demand.

MJF PA12GB 3D printing material is recommended for prototyping and manufacturing functional, large pieces, especially to avoid issues like warping in high-performance parts for applications like robotics, drones, medical devices, mechanical devices, and tooling. Shapeways offers MJF PA12GB in gray and dark gray. Find out more in the design guidelines here.

Nylon 12 [Versatile Plastic] with Selective Laser Sintering (SLS)

Nylon 12 [Versatile Plastic] is extremely popular–and true to its name–offers epic versatility. Reinforcing one of the greatest benefits in 3D printing with the ability to create complex geometries not possible in traditional manufacturing, Nylon 12 [Versatile Plastic] is used with Selective Laser Sintering (SLS) for 3D rapid prototypes as well as high-performance, functional models for applications like medical models.

Nylon 12 [Versatile Plastic] is unique thanks to its thinner form and ultimate flexibility, making it suitable for springs and interlocking parts. In its thicker state, it is strong enough for end-use parts in critical applications. Shapeways offers Nylon 12 [Versatile Plastic] in standard white, but parts can be dyed in numerous colors. This 3D printing material is also available in Natural, Processed, Premium, and Smooth finishes. Find out more in the design guidelines here.

Other prototyping use cases include:

Consumer Goods

For Noah Neibaron, CEO of Tilt Hydrometer, being able to prototype without limits made all the difference. This was true in product development as well as quality manufacturing of their 3D printed devices measuring fermentation for home-brewed beer. While some Shapeways customers may 3D print a few prototypes while iterating, Neibaron required over a hundred iterations to perfect parts.

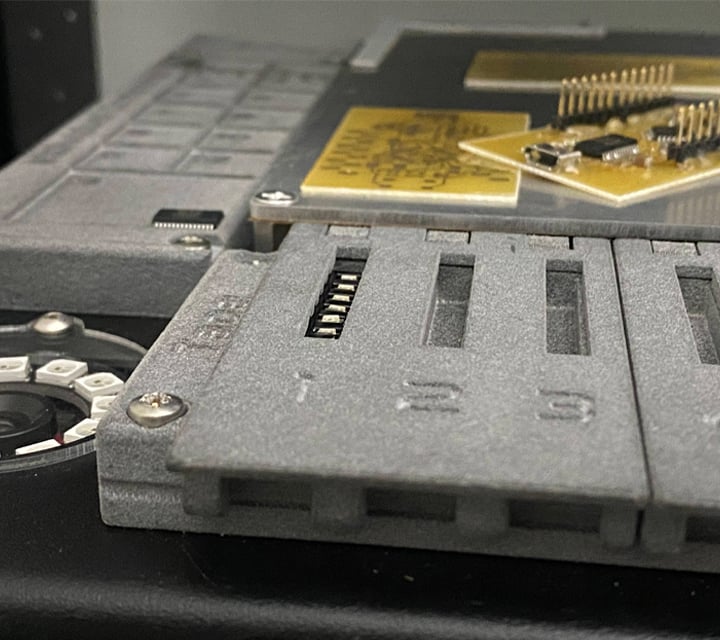

Electronics

The Botfactory team experienced their own frustrations in prototyping electronic circuit boards via traditional manufacturing, as well as noticing a lot of challenges for students in engineering Master’s programs doing similar work. In working with Shapeways they were able to 3D print entire circuit board printers as well as proving that 3D printed parts themselves can function over the long term in a high-performance capacity.

Fine Jewelry

Shapeways customers like Groen and Boothman, luxury jewelry designers, enjoy experimenting with and using an array of 3D printing materials and technology, from thermoplastics to precious metals. For their 3D printed Creatures bracelet series, however, they were able to use Nylon 12 [Versatile Plastic] for both prototyping of and final production of their high-end cuff bracelets.

Medical

Flamingo Works partners with Shapeways to 3D print medical training platforms for physicians performing robotic-assisted surgeries. There were a multitude of different parts designed for each learning task, making Nylon 12 [Versatile Plastic] and SLS 3D printing technology a great choice whether in prototyping or 3D printing high-performance parts for functional use.

Case Studies

Manufacture high-quality products in 90+ of the best materials and finishings, from plastics to metals.