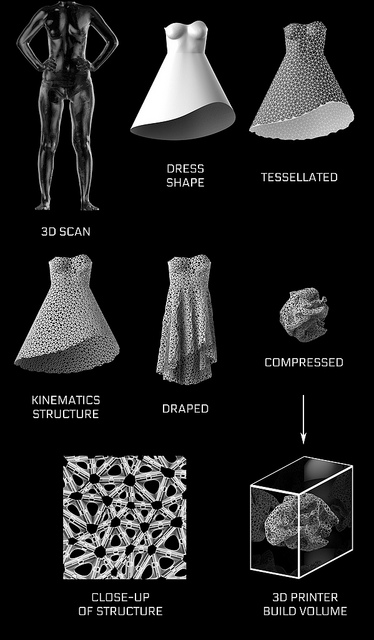

Nervous System have just released a new Kinematics jewelry range coupled with a customization app to create unique 3D printed jewelry based on interlocking components. While this is a beautifully simple interface to create customized 3D printed jewelry, it is the potential for draping and compression to fit a large design within a small 3D printer build size when using a process such as Shapeways Selective Laser Sintering that really makes this an impressive application for 3D printing.

Kinematics is a system for 4D printing that creates complex, foldable forms composed of articulated modules.

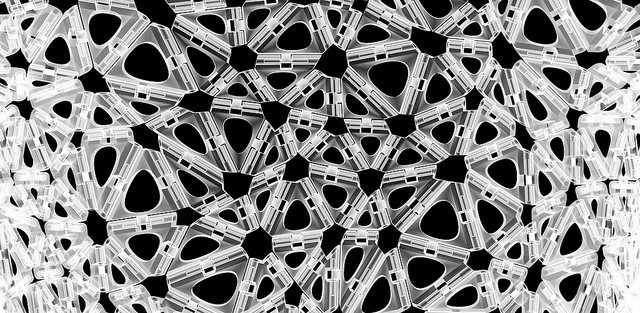

The system provides a way to turn any three-dimensional shape into a flexible structure using 3D printing. Practically, Kinematics allows us to take large objects and compress them down for 3D printing through simulation. It also enables the production of intricately patterned wearables that conform flexibly to the body. Kinematics produces designs composed of 10’s to 1000’s of unique components that interlock to construct dynamic, mechanical structures.

Each component is rigid, but in aggregate they behave as a continuous fabric. Though made of many distinct pieces, these designs require no assembly. Instead the hinge mechanisms are 3D printed in-place and work straight out of the machine.

Above for example, you see a full scale dress design that would be far too large to fit into even our largest printer that can take parts up to 650x350x550mm in Nylon. By converting the structure into a series of self folding connections the entire dress could be compressed down to the smallest possible form (whilst maintaining enough distance so parts do not sinter together) and then be 3D printed in our EOS slective laser sintering 3D printer in one entire print. We would then unfurl the dress from the print build, air blast the excess Nylon powder out of the dress and it would be ready to wear.

This project evolved out of a collaboration with Motorola’s Advanced Technology and Projects group which challenged Nervous System to create in-person customization experiences for low cost 3D printers. The genesis of the project is discussed at length in The Making of Kinematics post on the Nervous System blog.

The Kinematics apps are perfect to give people access to the power of customization through 3D printing for those who do not know how to 3D model. We are seeing more and more design for 3D printing apps plug into the Shapeways API that make it easy for anyone to create or customize a product for 3D printing. Nervous System were one of the pioneers with the Cell Cycle App with the Kinematics app taking the concept one step further with interlocking components including the Kinematics at Home that creates a bracelet you can 3D print with your 3D printer at home..

Nervous System is a generative design studio that works at the intersection of science, art, and technology. Designers Jessica Rosenkrantz and Jesse Louis-Rosenberg create using a novel process that employs computer simulation to generate designs and digital fabrication to realize products. Drawing inspiration from natural phenomena, they write computer programs based on processes and patterns found in nature and use those programs to create unique and affordable art, jewelry, and housewares. Founded in 2007,

Nervous System has pioneered the application of new technologies including 3D printing, webGL, and generative systems. Nervous System releases online design applications that enable customers to co-create products in an effort to make design more accessible. These tools allow for endless design variation and customization.

All images courtesy of Nervous System

So very cool and exciting. Great work from the team involved! Can’t wait to play…

WOW just what I was searching for. Came here by searching for travel

Looks nice. Also looks very, very fragile! (Teeny, tiny hinge pins, oh my.)

I knoww this web pge offers qualityy depending content and

extra information, is there any other site which provides these kinds of stuff in quality?

Makes me wonder about the triangle count of those hinged subunits – how many of those before they hit the 1m triangle limit ?

Very good question. I’m curious about that, too.