I'd like to share some postprocessing techniques about finishing a printed model having grainy surface texture, as printed with the strong and flexible powder plastic material. However, this technique should work as well for other surface textures.

This method can result in smooth surface without losing much detail of the models. This is my first finished model with Shapeways, a 1/24 scale racing driver with sunglasses (thus the object height is about 7 cm).

This is the painted version:

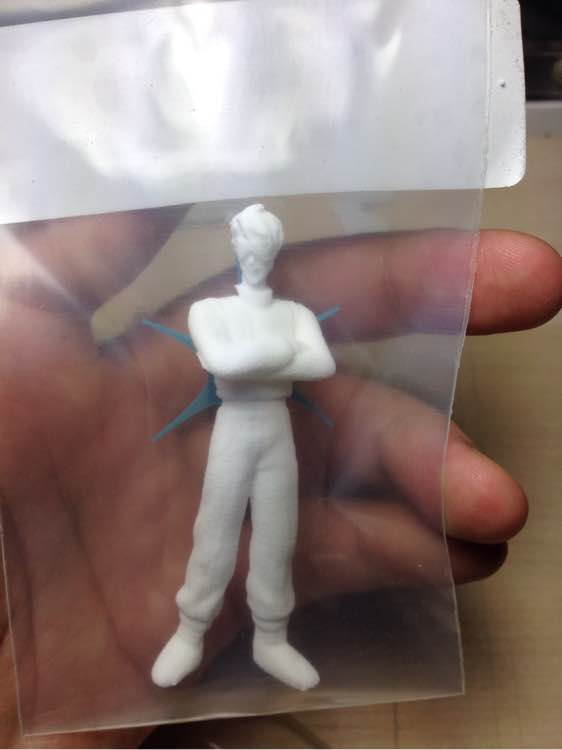

This is what I receive from Shapeways.

The post processing steps include the following:

1) Use thin superglue (such as thin CA) or lacquer clear paint to seal off the powered surface (apply directly onto the model and don't worry about over-applying, the material is porous at the surface and will absorb the glue, if applied too much, let the thin glue drip off).

2) Apply grey primer after sealing. (Then apply a different color primer for indicating smooth level when sanding, but because the base color is white, i used only grey primer in this example). Please note how porous the surface was at the head or other details - these details were not sanded or polished but were smoothed by the subsequent coats - see below.

3) Here's the initial sanding - the primary purpose is reduce the number of primer layers needed - but you may opt to use more layers of primers if sanding seems too troublesome. I also filled the gaps and filed away unwanted protrusions in the model (including the bottom shoe surfaces). I also drilled a 1 mm hole for later pinning and handling.

4) After rough sanding, apply more primer layers one by one - this will slightly increase the outer surface dimension but will not remove already existing structural details.

5) Here, the next layers of primers are white (because it's in preparation as a base color for subsequent painting).

6) A glossy coat of clear is applied to seal off the primer base coat. As you may see below, the original surface texture is removed. I masked off areas that will retain the base color.

7) Subsequent steps are all about painting. Use general painting and masking techniques to apply color coats one by one (or one may hand-paint freely). Someone may ask why didn't I just make a color model and print out the model directly. This is because the finish color and texture of 3D printing as of 2016 is far from desirable from a scale modeler's standpoint (e.g., color brilliance, level of surface property ranging from gloss to matt, etc.). This may change in the future with the improvement of the printing technology and indeed render this post pointless.

8) Here's the removal of masking tapes to reveal the colors. Then I hand painted details to finish. An additional matt clear coat will be applied to seal everything in.

I hope this post can be helpful to the community. Cheers!

The relevant product can be found here:

http://shpws.me/Mhw7