This post, originally published in 2013, was one of our most popular posts in 2017. Find out why below:

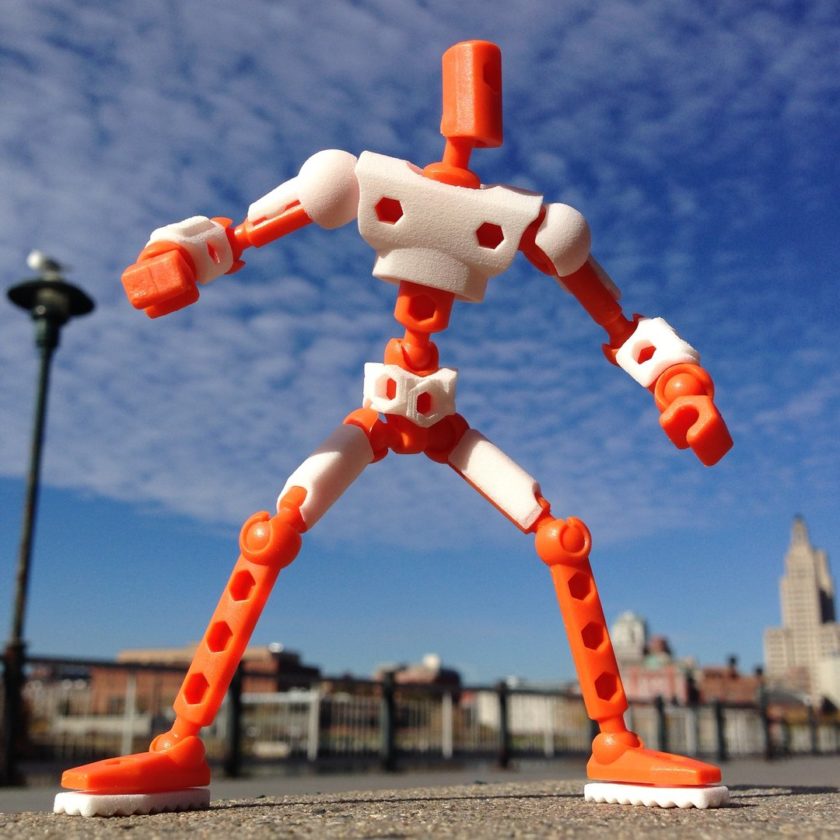

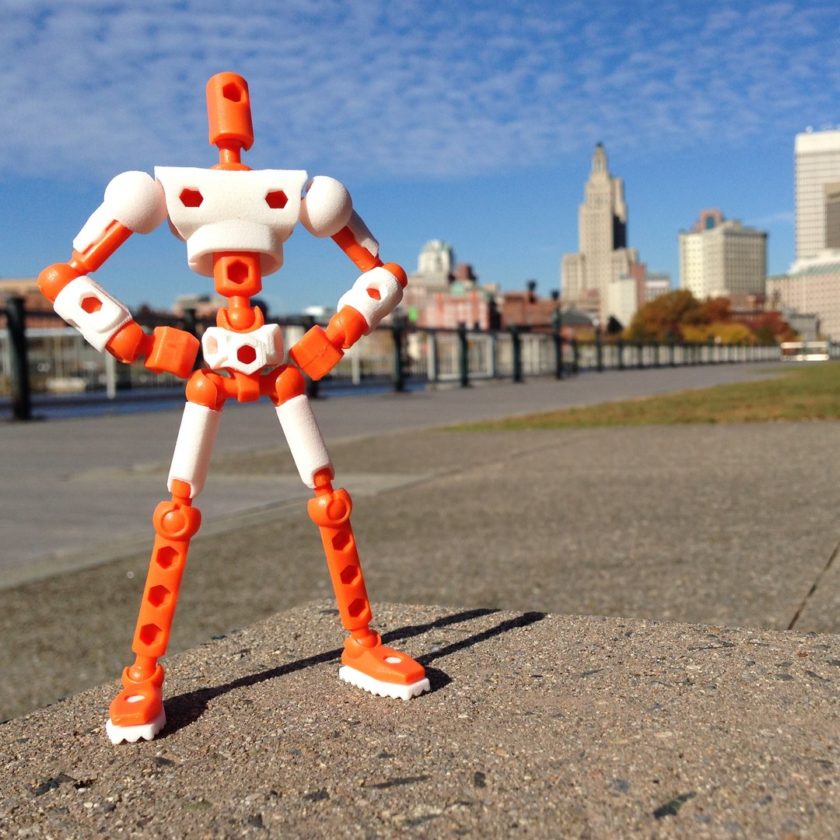

When designing an action figure to be 3D printed, the best way to create articulated components that are poseable is with snap-fit ball joints.

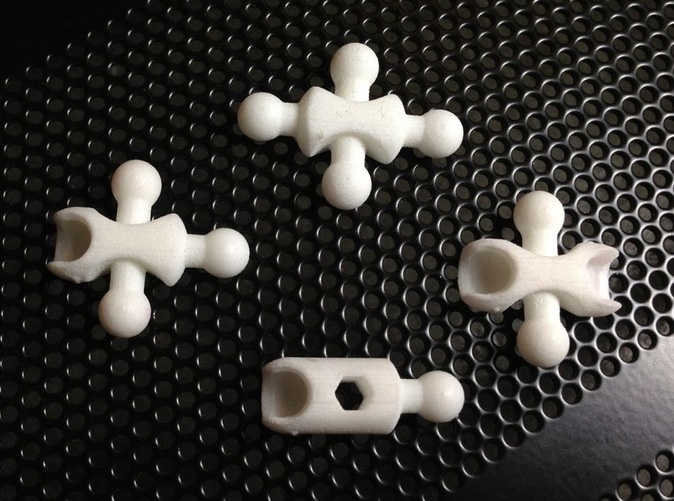

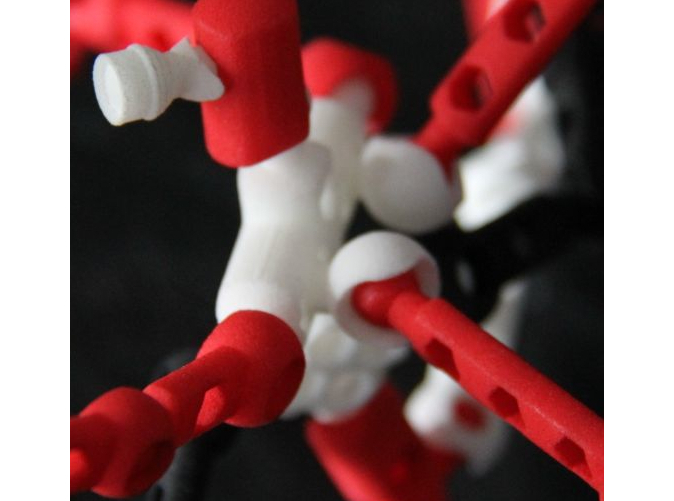

Ball joints work as snap-fit components and cannot be 3D printed together as the friction required to make the parts pose-able would result in the parts being fused together. When designing ball joints it is best to make them an ‘exact fit’ where the positive part (the ball) and the negative part (the socket) are the exact same circumference. You need to ensure the socket component is not entirely enclosed, more like a C shape to allow the part to expand slightly to snap it into place.

try it yourself

Shapeways laser-sintered Nylon is the best material for creating snap fit ball joints as the material is strong enough to withstand the stress of being snapped into place (our Frosted Detail Plastic might just snap). The Nylon also has a slightly granular surface that also help to make the parts to grip together. Also note that our polishing and dying process which has a smoother surface than the raw Nylon still grips together for a firm fit, you do not need to change the design to allow for change in surface finish or dimensional changes.

To see some really good examples of snap-fit ball joints designed for 3D printing, check out the ModiBot shop by Kid Mechano which has many really good examples of ball joints in action.